Instant Grab Adhesive

Instant Grab Adhesive: High Tack, Fast Grip & Immediate Hold

Adiseal instant grab adhesive provides a heavy-duty waterproof bond on many different construction materials and saves time with a strong immediate hold. It is suitable for both interior and exterior grab adhesive bonding applications due to its waterproof grab adhesive properties. This quick grip adhesive once cured, provides a high strength, flexible and durable waterproof adhesive bond.

- Why use instant grab adhesives?

- Best adhesive strength test results table

- Benefits of Adiseal Hi-Grab instant hold adhesive

- How to use instant grab adhesive

Why use instant grab adhesives?

Most adhesives take time to cure and reach full adhesion strength. During this curing period, the items you are trying to bond can move away from the surface you are trying to bond it to. To stop this, you might be required to use temporary supports to hold the item in place until the adhesive cures and reaches full bond strength.

The temporary supports have to be removed once the adhesive has cured which can increase the amount of time required to do the job. Using an immediate grab adhesive with quick extra high instant hold and instant tack may eliminate the need for temporary supports, saving time and money on labour costs.

Adiseal Hi-Grab instant grab adhesive

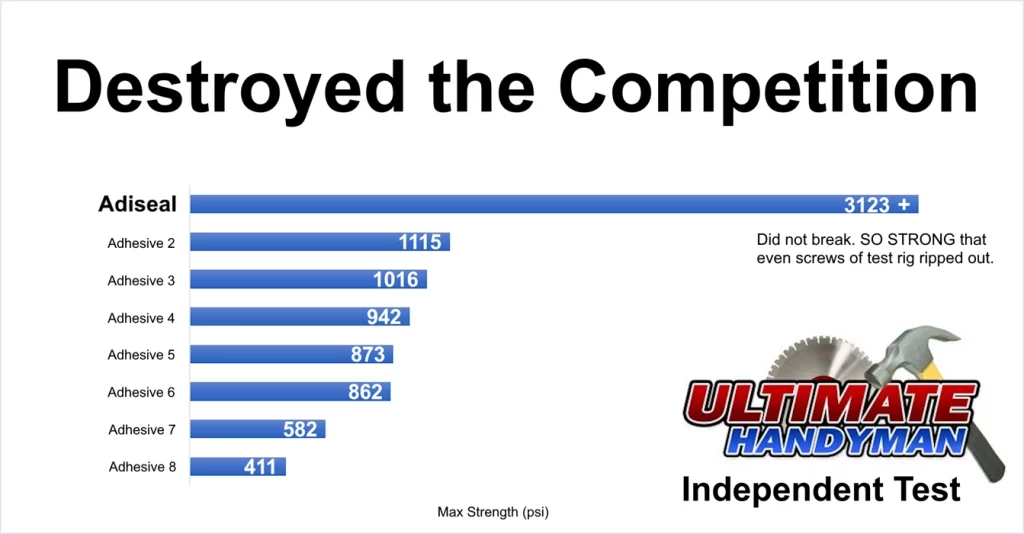

Adiseal Hi-Grab heavy duty instant hold adhesive is based on the same technology as the record breaking strongest adhesive, Adiseal adhesive sealant but now with even stronger instant grab and hold. In an independent adhesive strength test, Adiseal was shown to be over 3 times stronger than the next best adhesive. The bond strength of Adiseal in the test was too strong for even the test rig. The chart below shows the test results between wood and metal adhesive bond strength.

Best adhesive strength test results table

| Product | Max pressure when adhesive bond broke (psi) |

| Adiseal | 3123 + psi |

| SupaBond | 1115 psi |

| Tec 7 | 1016 psi |

| HB42 | 942 psi |

| Loctite PL Premium | 873 psi |

| Gorilla Grab Adhesive | 862 psi |

| Bond It PU18 | 582 psi |

| Bond It Save Nails | 411 psi |

“That is actually unbelievable!”

Testimonials

Testimonials & some comments on the: Grab adhesive tests 2017, video on YouTube

- That Adiseal is phenomenal!

- That Adiseal is some stuff though, definitely need to get some of that bought!

- I instantly went looking for Adiseal!

- Need to get my hands on some of that to try out.

- Looks like a cracking product.

- Having used the two most expensive brands on numerous occasions, I’ll be trying out the others, especially the Adiseal.

- Adiseal certainly surprised me in this test!

- Fantastic tests. It’s unbelievable that Adiseal test with the hardwood.

Benefits of Adiseal Hi-Grab instant hold adhesive

Adiseal Hi-Grab quickest grab adhesive has the following benefits:

- Ultimate high instant hold adhesive

- Extreme strength

- Works in dry, wet & even underwater

- Waterproof adhesive

- Strong adhesive bond

- Mould resistant

- Over paintable (with most paints)

- Non brittle (stays flexible)

- UV resistant

- Virtually odourless (no harsh solvent smell)

- Isocyanate free

- Solvent-free (safe for use on sensitive materials like mirrors and polystyrene)

- No shrinkage or cracking

- Permanently flexible

- Prevents fungal growth

- Prevents bacteria growth

- Good resistance to chemicals

- EC1 Plus certified (no VOC)

- Indoor and outdoor adhesive

- Suitable for interior and exterior bonding

Adiseal Hi-Grab construction adhesive is available in white colour in 290ml cartridges. To get it in any other RAL colour, please contact us.

Instant grab adhesive hold performance demonstration

In the video below, witness the phenomenal instant power grab and bond strength of Adiseal Hi-Grab instant hold adhesive. We conducted a test using 32 Kg concrete blocks. To push it to the extreme, we applied the high tack adhesive on the edge of the concrete with a smaller surface area instead of the side with the largest surface area. As shown in the video below, the two concrete slabs immediately gripped each other thanks to the incredible instant power grab and bond strength of Adiseal Hi-Grab quickest grab adhesive.

Bonding items with Adiseal Hi-Grab

How to use instant grab adhesive

How to use instant grab adhesive.

- Prepare the surfaces

Ensure that the surfaces you are bonding are clean, dry, and free from dust, grease, or any other contaminants. Proper surface preparation is crucial for a strong bond.

- Cut the tip

Cut the nozzle of the cartridge to the correct size required.

- Apply the adhesive

Apply the adhesive evenly on one surface, ensuring a robust bond without excess that might seep out when joined. Due to their thickness, instant grab adhesives usually require a high-quality caulking gun (sealant gun) for efficient cartridge dispensing.

- Join the surfaces

Press the two surfaces firmly together, aligning them properly. Make sure the adhesive spreads evenly between the surfaces. Apply pressure for a few seconds to ensure a good initial bond.

- Secure or support if needed

In some cases, you may need to use temporary supports or clamps to hold the bonded surfaces in place while the adhesive cures.

- Curing time

These adhesives provide a high initial grip, but they may still require some time to fully cure and reach their maximum strength. Refer to the manufacturer’s instructions for the recommended curing time.

- Clean up

Immediately remove any excess adhesive that may have squeezed out during the bonding process. You can use a suitable solvent or cleaner recommended by the adhesive manufacturer.

Tip: To store Adiseal once opened, leave about 1cm worth of product out of the nozzle and store the tube upright in a cool dry place. Adiseal requires moisture for it to cure. The exposed part out of the nozzle will cure creating a cap. To re-use Adiseal, pull the cured part out or cut the nozzle until the uncured part is reached.

Where to buy instant grab adhesive

In the UK, to buy instant grab adhesive, please contact us for details of your local stockist. For other countries, our products can be purchased from www.guglue.com

There may also be a distributor for your country or an opportunity to become our distributor. Contact us for more information.

Data Sheets

Frequently Asked Questions About Instant Grab Adhesive

Grab adhesives may offer less initial grip than products with instant grab. In situations of insufficient initial strength, temporary supports might be necessary until the adhesive reaches its maximum holding power during curing. This issue is more noticeable on vertical surfaces where items can slide down.

They provide multiple benefits, such as quick bonding, no need for temporary supports, and immediate handling of bonded items. They are generally thicker, ensuring strong initial grip and bonding strength.

Some products like Adiseal Hi-Grab are designed to be waterproof, making them suitable for both indoor and outdoor applications. They can withstand exposure to moisture, ensuring a reliable bond even in damp or wet environments.

Yes, there are outdoor adhesives designed to endure moisture, UV radiation, temperature fluctuations, and outdoor elements. Adiseal is weatherproof meaning it is suitable for both indoors as well as outdoors.

Adiseal Hi-Grab provides extremely fast grab and holds an incredibly high weight without the item moving or falling. This saves time and money on labour costs as it eliminates the use of temporary supports.

Adiseal Hi-Grab is an adhesive with extra high grab and powerful strong bond strength.

Adiseal Hi-Grab adhesive provides superior grab when attempting to bond heavy items. It’s extra strong heavy-duty grab eliminates the need for temporary supports in many bonding applications. Adiseal Hi-Grab has been shown to have higher grab than other adhesives on the market.