Construction Adhesive

Construction Adhesive: Adiseal Strong Bond on Building Materials

Adiseal is a high performance construction adhesive that provides a strong, waterproof and heavy-duty bond on many different types of building materials. Its versatile, waterproof and UV resistant formula makes it suitable for both interior and exterior use.

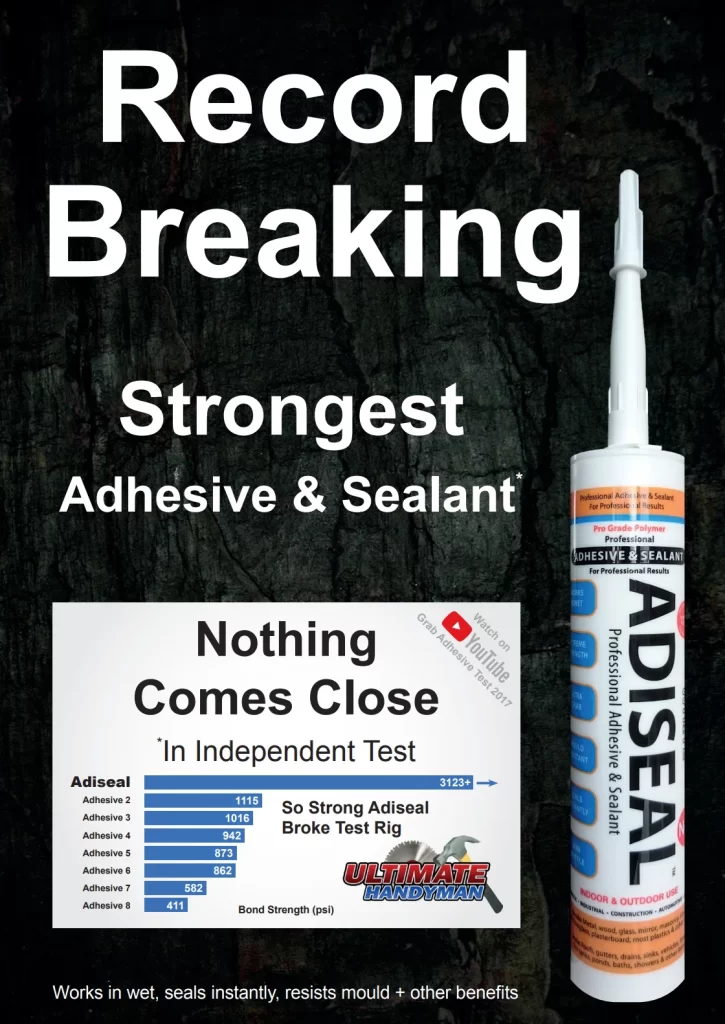

In an independent adhesive strength test, Adiseal has been shown to be the strongest construction adhesive. Adiseal also has high gap-filling properties, is highly durable and stays permanently flexible. It provides a long-lasting and high-strength bond on many different types of building adhesive applications.

- What is the best construction adhesive?

- What are the benefits of Adiseal construction adhesive?

- Materials Adiseal bonds

- How to use a construction adhesive

What is the best construction adhesive?

When looking for a building adhesive or construction glue to carry out building work or DIY repairs, a question often people ask is what is the best construction adhesive? In an independent construction adhesive strength test carried out by Ultimate Handyman, Adiseal proved to be the best adhesive. The high performance of Adiseal surpassed all competitors, displaying over three times the strength of the next best product.

The incredible strength of Adiseal led to the test on it forced to be abandoned as the screws holding the metal sheet down began to rip out, and even the hydraulic ram seal broke. The strength of Adiseal was so strong that it surpassed the capacity of the test rig to handle.

Strongest construction adhesive test results

“That is actually unbelievable!”

Ultimate Handyman

Testimonials

What about other construction adhesives?

Whilst there are many different construction adhesive sealant and construction glue products available, other products were not tested in this video as they had already been tested previously by Ultimate Handyman. In these previous tests, products from Soudal, Everbuild, Geocel & C-Tec CT1 were tested along with the old formula of Adiseal.

What are the benefits of Adiseal construction adhesive?

Materials Adiseal bonds

Adiseal is a versatile product that provides a durable and strong bond on many different types of building materials including:

Details of benefits

Strongest waterproof construction adhesive

Adiseal is the strongest waterproof construction adhesive sealant, suitable for dry, damp, wet, and underwater applications. It also offers excellent resistance to mould growth. In tests, Adiseal demonstrated superior performance and the strongest resistance to mould.

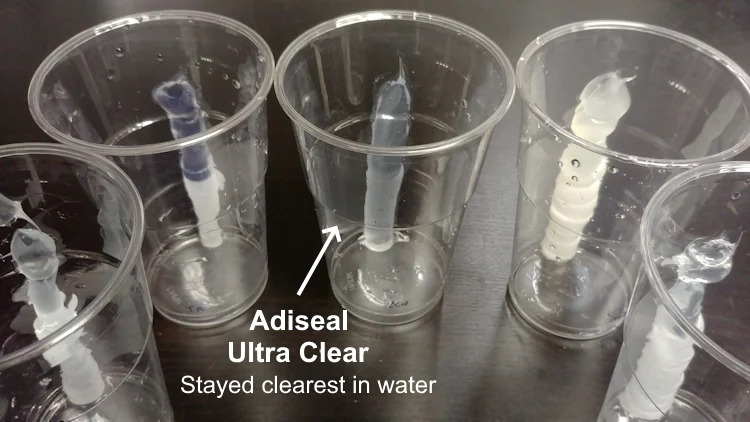

Clear construction adhesive in water

In our test, Adiseal Ultra clear construction adhesive sealant outperformed others by maintaining its clarity in water, while competing products turned white.

Adiseal Ultra clear construction adhesive is truly transparent, unlike other products labeled “clear” that appear cloudy. The image below shows Adiseal’s clarity compared to a cloudy competitor.

Exterior uses

Adiseal serves as an ideal exterior construction adhesive sealant due to its waterproof properties and ability to withstand various outdoor weather conditions. It provides a durable high-strength bond and seal in both interior and exterior applications.

Instant Grab

Adiseal boasts a high initial grab, providing a strong hold on dry or wet surfaces. For even stronger heavy-duty instant grab adhesive, Adiseal Hi-Grab offers stronger initial grab, eliminating the need for temporary supports while the adhesive dries.

Gap Filling Adhesive

Adiseal offers high gap fill for uneven surfaces and remains in place without slumping, making it suitable for overhead and vertical applications, ensuring a secure bond.

Flexible Construction Adhesive

Adiseal is a flexible, non-brittle adhesive that absorbs stress from vibration and temperature changes, unlike rigid adhesives that crack under pressure.

Solvent Free

Adiseal is solvent-free, making it safe for delicate materials like mirror backing and polystyrene, unlike solvent-based alternatives. It’s ideal for sensitive projects.

No Shrinkage or Cracking

Unlike solvent based products, Adiseal doesn’t shrink or crack during curing, thanks to its solvent-free composition, resulting in a stronger bond.

How to use a construction adhesive

How to use a construction adhesive

- Prepare the Surfaces

A clean surface provides the best potential for a strong adhesive bond therefore before applying the adhesive, clean surfaces thoroughly to remove dust, grease, or old adhesive.

- Cut the Cartridge

If you are using a cartridge-based construction adhesive, use a utility knife to cut off the tip of the cartridge. The size of the opening will depend on the desired bead size and the project requirements.

- Apply the Adhesive

Squeeze the trigger of the caulking gun or adhesive applicator to start applying the adhesive in a continuous bead along the surface.

- Press Surfaces Together

Press the surfaces together firmly to establish proper contact between the adhesive and both materials. Clamps or other supports can help maintain this pressure during the curing process if needed.

- Clean Excess Adhesive

Use a clean cloth or a putty knife to remove any excess adhesive that may have squeezed out from the bond line.

- Curing Time

Let the product cure completely before subjecting it to stress or load. The curing duration may vary based on factors like temperature, humidity, and the adhesive type.

Tip: To store Adiseal once opened, leave about 1cm worth of product out of the nozzle and store the tube upright in a cool dry place. Adiseal requires moisture for it to cure. The exposed part out of the nozzle will cure creating a cap. To re-use Adiseal, pull the cured part out or cut the nozzle until the uncured part is reached.

Construction adhesive for concrete

Adiseal is a versatile construction adhesive for concrete and other materials. It can be applied to porous materials without sealing the concrete beforehand, as it bonds directly to porous concrete. Our concrete demonstration block below shows the Adiseal heavy duty adhesive strength in attaching different materials to concrete.

On the concrete demo block, no primer was used to seal it before applying Adiseal adhesive sealant. It was simply cleaned thoroughly by brushing it. A fine brush like a painting brush helps remove fine dust.

Construction adhesive for stone

Adiseal builders adhesive creates a strong, waterproof bond on stone surfaces like marble and granite. Adiseal Hi-Grab offers a powerful instant grip, eliminating the need for temporary supports during setting. Stones don’t require pre-sealing as Adiseal doesn’t bleed or stain them.

Data Sheets

Colours

Adiseal adhesive and sealant is available in the following colours:

- White adhesive and white sealant

- Black adhesive and black sealant

- Grey adhesive and grey sealant

- Clear adhesive and clear sealant

- Brown adhesive and brown sealant

Adiseal can also be manufactured in any RAL colour.

Where to buy construction adhesive UK

To buy construction adhesive in the UK, please contact us for your nearest stockist. For customers outside of the UK, you can buy Adiseal construction adhesive from your local distributor. If there is no distributor in your country, visit www.guglue.com for worldwide shipping.

Frequently asked questions about construction adhesive

Adiseal has been shown to be the strongest construction adhesive in an independent adhesive strength test carried out by Ultimate Handyman. Adiseal was shown to be over 3 times stronger than the next best product.

Yes, there are construction adhesives specifically designed for outdoor use. These adhesives are formulated to withstand exposure to moisture, temperature variations, and other environmental factors.

The hardness of construction adhesive depends on the type of product. Adiseal has been formulated to stay permanently flexible. This gives it the advantage of providing a durable and non-brittle bond.

It is possible to use it as glue if the surface area there it needs to be applied to is large. As a general rule, it is better to use glue for bonding items with small surface areas and adhesive on large surface areas.

Adiseal has been shown to be the strongest construction adhesive in an independent adhesive strength test. Adiseal was found to be over 3 times stronger than any other adhesive tested and the the adhesive bond did not break at even over 3123 psi whereas all other adhesives broke at 1115 psi or less.

Adiseal is proven to be the strongest construction adhesive in an independent test. It delivers a robust, flexible, waterproof, and highly durable bond on various stone types, including marble and granite. With Adiseal Hi-Grab, you get strong, heavy-duty instant grab, eliminating the need for temporary supports while the adhesive cures.

Some products like Adiseal are a versatile product that can be used on a wide variety of materials like wood. It provides a strong, flexible, waterproof and durable bond on wood to wood bonding or wood to many other building materials.

Some building material bonding products set hard once cured. This can lead to a brittle bond that can crack and break with movement or vibration in the substrate. Adiseal is designed to stay flexible allowing for movement in the substrate without the bond becoming weak. This can make the bond highly durable resulting in a bond that lasts a lot longer.