Bond Metal

Strong Adhesive for Metal: Flexible & Durable Bond to Glue Metal

To glue metal with an adhesive, Adiseal has been shown to be the strongest adhesive for metal in an independent metal to metal adhesive bond strength test. It was also the strongest in a wood to metal adhesive bond strength test. Adiseal is suitable at bonding, sticking and gluing many different types of metals including steel, aluminium, iron, copper, brass, lead and many more. Adiseal is our best adhesive for metal, providing a strong, flexible, waterproof and durable adhesive bond on many different materials.

- What is the best adhesive to bond metal

- How to stick metal with a metal glue adhesive

- Benefits of Adiseal adhesive for metal

- What materials will Adiseal bond to metal

What is the best adhesive to bond metal

Adiseal is our best adhesive for metal to metal bonding and other materials. It has been shown to be the strongest adhesive in an independent metal to metal adhesive glue strength test by Ultimate Handyman. The table below shows the results of the test, where Adiseal was stronger than all other adhesives tested on metal to metal bonding.

Strongest Metal to Metal Adhesive Strength Test Results

- Adiseal : 245 psi

- SupaBond : 224 psi

- Tec 7 : 165 psi

- HB42 : 184 psi

- Loctite PL Premium : 202 psi

- Gorilla Grab Adhesive : 166 psi

- Bond It PU18 : 136 psi

- Bond It Saves Nails : 95 psi

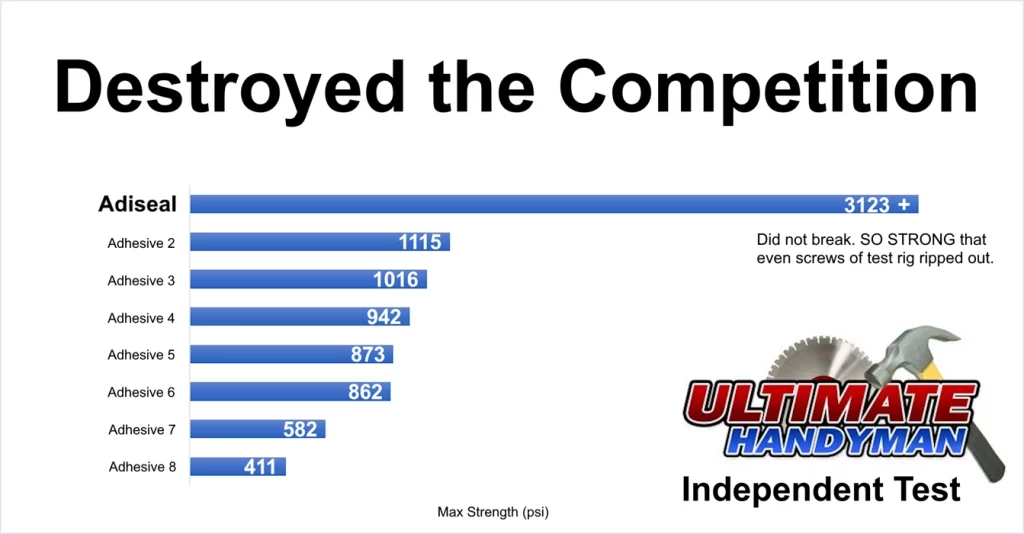

As well as Adiseal adhesive sealant being the strongest product for metal to metal bonding, it is also the best adhesive at sticking wood to metal together. In an independent wood to metal adhesive strength test by Ultimate Handyman, Adiseal was over 3 times stronger than the nearest competitor. In fact, it was so strong that the screws holding the metal sheet down started to rip out forcing the test on Adiseal to be stopped.

Test results

During the adhesive bond strength test between wood and metal, Adiseal demonstrated remarkable resilience, enduring a substantial pressure exceeding 3123+ psi. In stark contrast, all other product bonds faltered under pressures of 1115 psi or less. The image chart below shows Adiseal’s outstanding performance in the adhesive strength test, proving it’s the best adhesive.

Best wood to metal adhesive strength test results table

| Product | Max pressure when adhesive bond broke (psi) |

| Adiseal | 3123 + psi |

| SupaBond | 1115 psi |

| Tec 7 | 1016 psi |

| HB42 | 942 psi |

| Loctite PL Premium | 873 psi |

| Gorilla Grab Adhesive | 862 psi |

| Bond It PU18 | 582 psi |

| Bond It Save Nails | 411 psi |

“That is actually unbelievable!”

Testimonials

Testimonials & some comments on the: Grab adhesive tests 2017, video on YouTube

- That Adiseal is phenomenal!

- That Adiseal is some stuff though, definitely need to get some of that bought!

- I instantly went looking for Adiseal!

- Need to get my hands on some of that to try out.

- Looks like a cracking product.

- Having used the two most expensive brands on numerous occasions, I’ll be trying out the others, especially the Adiseal.

- Adiseal certainly surprised me in this test!

- Fantastic tests. It’s unbelievable that Adiseal test with the hardwood.

Adhesive bond strength demonstration on metal

To demonstrate the strength of Adiseal, we bonded 2 metal steel hook plates together with Adiseal. Once the product cured, we then used the steel hook plates to tow a 2.7 tonne van to demonstrate the high bond strength of Adiseal on metal to metal bonding. The images below show the process of our demonstration.

Our demonstration showed the ability of Adiseal to stay bonded between the metal plates without breaking even under heavy stress. The video below shows how we carried out the demonstration.

How to stick metal with a metal glue adhesive

How to stick metal with a metal glue adhesive

- Surface preparation

Clean the metal surfaces that will be bonded together. Remove any dirt, grease, oil, rust, or other contaminants using an appropriate cleaner or solvent.

- Spray water

Adiseal requires moisture for it to cure which it normally gets from the air. If applying the adhesive between 2 non-porous materials like metal, spray a little water onto the material surface before applying the adhesive.

- Apply the adhesive

Apply the adhesive evenly onto one of the metal surfaces. Apply enough adhesive to create a sufficient bond, but avoid excessive application that can cause squeeze-out or messiness.

- Join the metal surfaces

Align the metal pieces together and firmly press them together. Apply pressure to ensure good contact between the surfaces and to spread the adhesive evenly. Sliding the items side to side can help spread the adhesive to cover more surface area.

- Temporary supports

Use clamps or other holding mechanisms if necessary to keep the pieces in place during curing.

- Curing time

Allow the adhesive to cure as per the manufacturer’s instructions. The curing time can vary depending on the adhesive type and specific product. Follow the recommended curing temperature and humidity conditions for optimal bonding strength.

- Post-curing and handling

After the adhesive has cured, avoid stressing the bonded area for the recommended post-curing time. This allows the adhesive to reach its maximum strength. Once fully cured, handle the bonded metal with care and avoid subjecting it to excessive forces or stresses that could compromise the bond.

Tip: To store Adiseal once opened, leave about 1cm worth of product out of the nozzle and store the tube upright in a cool dry place. Adiseal requires moisture for it to cure. The exposed part out of the nozzle will cure creating a cap. To re-use Adiseal, pull the cured part out or cut the nozzle until the uncured part is reached.

What materials will Adiseal bond to metal

Read the individual section for more details.

As well as bonding metal, Adiseal can also be used to seal metal.

Adiseal adhesive will successfully stick stainless steel panels, glue aluminum and bond many other metal items.

Using Adiglue to glue metal to metal

It is also possible to glue metal to metal using our Adiglue. Although Adiglue is less brittle than super glues, it is still not as flexible as Adiseal adhesive & sealant.

Benefits of Adiseal adhesive for metal

- Works in dry, wet, even underwater

- Strong initial grab

- Waterproof adhesive and sealant

- Fast power grab and grip

- Gap filler adhesive

- Resists mould

- Over paintable

- Non brittle (stays flexible)

- UV resistant

- Virtually odourless (no harsh solvent smell)

- Isocyanate free

- Solvent free (safe for use on sensitive materials like polystyrene and mirrors)

- No shrinkage or cracking

- Flexible adhesive

- Prevent fungal growth

- Prevent bacteria growth

- Good resistance to chemicals

- EC1 Plus certified (no VOC)

- ISEGA certified – safe for use in food preparation areas

- Suitable for interior & exterior use

The standard adhesive drying time for Adiseal is 24 – 48 hours to fully cure. Curing times can increase in colder temperatures.

Colours

Adiseal adhesive and sealant is available in the following colours:

- White adhesive and white sealant

- Black adhesive and black sealant

- Grey adhesive and grey sealant

- Clear adhesive and clear sealant

- Brown adhesive and brown sealant

Adiseal can also be manufactured in any RAL colour.

Please note Adiseal colours provides a stronger bond on metal and other materials compared to the clear version.

Where to buy metal adhesive

In the UK, to buy metal adhesive please contact us for details of your local stockist. For other countries visit www.guglue.com

Mechanical fixings

It is also possible to attach metal with mechanical fixings. One way would be to drill metal then use mechanical fixings. Adiseal Ultimate metal drill bit drills faster and drills more holes than any other metal drill bit.

Frequently asked questions about bonding metal

You can join metal to metal without welding by using mechanical fasteners, rivets, or adhesive. When using adhesive, ensure both surfaces are clean, removing any oil or grease. Apply the adhesive, press the metal together, and maintain pressure until the adhesive dries. Temporary supports may be needed during the drying process.

Adiseal is the strongest adhesive in an independent test. It was strongest in the metal to metal bonding strength test. It was also over 3 times stronger than anything product in the wood to metal glue adhesive strength test.

The strongest adhesive in an independent metal to metal glue adhesive strength test was Adiseal. It also was strongest in the wood to metal glue bonding strength test.

Surface preparation is vital for a strong bond. Clean the metal surface to eliminate dirt, grease, oil, or rust. You can enhance adhesion by abrasion with sandpaper or a wire brush. Depending on the adhesive and metal type, additional surface treatments like primers or etching agents may be necessary.

Metal bonding adhesives are versatile and can often bond metal to other materials like plastic, glass, ceramics, or composites. However, ensure you choose product compatible with both the metal and the material you intend to bond. Adiseal is a versatile product that bonds many different materials together.

Adiseal has been shown to be the strongest adhesive in an independent metal to metal adhesive strength test. The adhesive bond on Adiseal broke at 245 psi whereas all other adhesives broke at 224 psi or lower in the metal to metal adhesive bond strength test. Adiseal also provides flexible, waterproof and durable bond.

Adiseal adhesive provides a strong, flexible, waterproof and durable bond between metal and concrete. Adiseal has also been shown to be the strongest adhesive in an independent adhesive strength test.

Adiseal is a very versatile product that can stick metal to a wide variety of materials. These include wood, plastic, stone, concrete, brick, granite, marble, ceramic, glass, mirror, travertine, masonry and many other materials.