Seal Lead

LEAD SEALANT: Seal Lead Sheet, Flashing & Roof

Adiseal lead sealant adhesive is a high-performance product that will stick and seal lead sheet or flashing. When it comes to seal lead flashing, there are numerous products on the market. While certain lead sealants may provide temporary solutions, their effectiveness tends to diminish over time.

We will explore the reasons behind this issue and highlight why Adiseal stands out as the superior choice for sealing lead, lead pointing sealant, sealing flashing, sealing roofs as well as adhering to and securing lead flashing.

- Best sealant for lead flashing

- How to seal lead flashing

- Adhesive for lead flashing

- Where to buy lead sealant

Best sealant for lead flashing

The reason why Adiseal is the best lead sealer & flashing adhesive is because Adiseal is:

- Strongest adhesive

- Seals instantly

- Provides a permanent seal

- Stays permanently flexible

- UV resistant

- Cold applied

- Resists mould growth

- Solvent free

- Waterproof sealant

- Waterproof adhesive

- Works in dry, wet & even underwater

- Seals and bonds lead to a wide variety of building materials

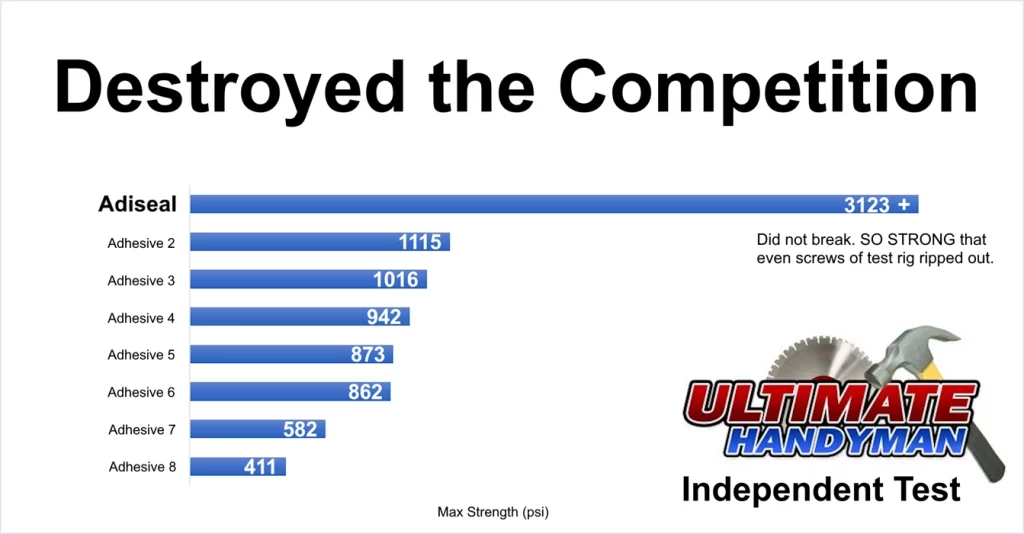

Strongest Adhesive

As well as Adiseal being a great sealant, it also proved to be the strongest adhesive in an independent adhesive strength test by Ultimate Handyman. In the test Adiseal was over 3 times stronger than the nearest competitor. Further details of the test are on the Adiseal page.

In fact, Adiseal was so strong that the screws holding the test rig down started to rip out, forcing the test on Adiseal to be stopped.

Adiseal will not only seal the lead flashing but it will also provide the strongest bond whether the lead flashing is being fitted to a rendered wall, a pitched roof or any other surface. Adiseal will also stick roofing felt to lead.

Seals instantly

Adiseal seals instantly, allowing for an immediate check of roof repairs. After completing the repair, test it by pouring water on the seal to confirm its success.

Provides a permanent seal

When using Adiseal to repair lead flashing, Adiseal will also provide a permanent fix as well as an emergency repair. If done correctly, the seal will last for years.

Permanently flexible

Adiseal remains permanently flexible, unlike products that become brittle due to temperature-induced expansion and contraction. Brittle products can crack or break, leading to water leaks. Adiseal’s enduring flexibility ensures a longer-lasting seal compared to its competitors.

UV resistant

If the product is not UV resistant, there is a high chance it will fail very quickly. A roof is one of the main areas of a property where it will receive high UV radiation from the sun. Adiseal is UV resistant, allowing durable seals on roofs.

Solvent free

Adiseal lead sealer, being solvent-free, avoids the common issue of shrinkage seen in other products. These products require solvent evaporation for curing, causing them to shrink and detach from the surface. Cheaper products often contain more solvents, resulting in weaker bonds compared to Adiseal.

Solvent-based lead adhesives and sealants can also harm sensitive materials like polystyrene, commonly used in building insulation for roofs, walls, and other areas.

Works in dry, wet & even underwater

As Adiseal works in dry, wet & even underwater, it’s possible to carry out an emergency repair on a leak even if it’s raining outside. It’s possible to carry out sealing duties even with rain pouring outside.

Lead sealant colours

Adiseal sealant and adhesive is available in a number of colours including grey to closely match the colour of the lead flashing. It is available in white, black, grey, brown & ultra clear.

Other uses

Adiseal is a muti-purpose product & will also fix a leaking gutter & repair a felt roof.

How to seal lead flashing

How to seal lead flashing.

- Prepare the Surface

Ensure the lead surface is clean, dry, and free from dust, dirt, or any contaminants. Use a wire brush or sandpaper to remove any loose particles or oxidation from the lead surface. Wipe it down with a clean cloth to ensure it’s completely clean.

- Apply the Sealant

Apply a bead of sealant along the desired area you want to seal, such as joints or gaps.

- Smooth and Shape the Sealant

Use a caulking tool, putty knife, or your finger to smooth and shape the applied sealant. This helps to ensure proper coverage and adhesion. It also helps to create a neat and professional-looking finish.

- Allow for Curing

Allow the sealant to cure as per the manufacturer’s instructions. This usually involves leaving it undisturbed for a specific period until it fully sets and forms a strong bond. Avoid exposing the sealed area to moisture or stress during the curing process.

- Check for Leakage

Once the sealant has cured, inspect the sealed area for any signs of leakage or gaps. With some sealants like Adiseal, this can be done instantly without waiting for the product to cure. If necessary, apply an additional layer of sealant to reinforce the seal and prevent any potential water penetration.

- Clean Up

Clean any excess sealant or smudges with a damp cloth or mineral spirits, following the manufacturer’s instructions. It’s best to remove excess sealant before it fully cures to ensure an easier clean-up process.

Adiseal is a muti-purpose product & will also fix a leaking gutter & repair a felt roof.

Adhesive for lead flashing

As well as Adiseal being a great sealant for lead flashing, it is also a great adhesive for flashing.

The advantage of Adiseal over other lead adhesives is it will also provide a strong waterproof seal as well as sticking the roofing felt.

Adiseal also proved to be the strongest adhesive in an independent test carried out by Ultimate Handyman, as detailed above.

Whether Adiseal is being used at repairing a lead roof, fit lead flashing, installing lead flashing, sealant for lead flashing or used as a lead point sealant, Adiseal is the best product for the job.

How to stick lead flashing

To stick roof lead flashing with adhesive, make sure the surface where the adhesive will be applied is thoroughly clean. Use a brush to remove any loose debris. Adisolve solvent cleaner is the ideal product to clean and remove oil, grease, tar, bitumen and many other stubborn deposits. Using a fine brush like a painting brush can help remove fine dust.

Adiseal can be applied directly without the need for a blowtorch. Simply apply Adiseal adhesive sealant to one surface and press down the lead flashing.

Adiseal can take 24 to 48 hours to fully cure but the sealing of the lead is done instantly. This allows the installer to test if the lead flashing has sealed instantly instead of testing it on another day. Pour some water over the seal to see if sealing of the lead has been done correctly.

As well as Adiseal being an adhesive for lead it will also bond other metals. Visit the dedicated page on how to bond metal for more details.

Colours

Adiseal lead sealant adhesive is available in the following colours:

- White adhesive and white sealant

- Black adhesive and black sealant

- Grey adhesive and grey sealant

- Clear adhesive and clear sealant

- Brown adhesive and brown sealant

Adiseal can also be manufactured in any RAL colour.

Please note Adiseal adhesive sealant colours provide a stronger bond compared to the clear version.

Where to buy lead sealant

To buy lead sealant in the UK, please contact us for details of your local stockist. For other countries that do not have a Adiseal distributor, you can buy from www.guglue.com

Frequently asked questions about lead seal

If applied correctly, Adiseal will repair the leak instantly on a leaking roof. It can take Adiseal 24 to 48 hours to fully cure but the seal is immediate.

Yes, Adiseal will stick the lead flashing that has peeled off. It will provide a very strong long lasting bond and will also seal at the same time.

Yes, Adiseal will stick roofing felt to lead. Make sure the surfaces are thoroughly clean to get the best result.

Yes with Adiseal, sealing lead can be done in the dry or wet. This makes it ideal for carrying out a permanent fix as well as emergency repairs.

Adiseal can be used to stick lead flashing. It is extremely strong, flexible, waterproof and UV resistant. It has high initial grab and can work as a lead seal at the same time.

Lead sealants are formulated to adhere to lead surfaces effectively, creating a watertight seal. They provide excellent adhesion and flexibility to accommodate the expansion and contraction of lead due to temperature changes.

Proper surface preparation, following the manufacturer’s instructions, and applying the sealant as recommended will contribute to a strong and long-lasting seal. Ensure the sealant fully covers the intended area and maintains contact with the lead surface.

Adiseal will provide a strong bond and waterproof seal on lead flashing. It has been shown to be the strongest products in an independent test.