Adhesive Guide

Adhesive Guide: Detailed Information from the Experts

Adhesive products are used in lots of different applications today to stick things together. This article is a detailed guide on adhesives. It will look at the history, science, adhesion, applications, different types of adhesives, advantages & disadvantages of using adhesives. Some of the questions answered in this article include:

- What is an adhesive?

- What are the advantages & disadvantages of using adhesives?

- How does an adhesive work?

- What alternatives are there to attach items together?

- When were they first used?

- What are the different types of adhesives available?

- How to use adhesives?

- Why do bonds fail?

- How to improve adhesion?

- How to remove adhesives?

- What is the different between adhesive and glue?

- Why doesn’t it stick to the tube?

- What to consider when choosing which adhesive to use?

What is an adhesive?

An adhesive is a material that attaches 2 materials together. This method is different to using mechanical methods of holding items together. Adhesives have many advantages and disadvantages compared to mechanical methods of attaching materials. There are natural and synthetic made adhesives available. Most products are either applied in a liquid or paste form which increases in bond strength as it dries. They are used in different application including manufacturing, construction and repair.

Alternatives to adhesives

Alternative methods of attaching two materials together are mechanical methods. These include:

- Mechanical fasteners like screws, nails, dowels, Velcro, rivets, rope, chain, clips, and clamps to name a few

- Welding

- Sewing with a thread

What are the advantages and disadvantages of using an adhesive?

Advantages of using an adhesive over mechanical methods

There are many advantages of using adhesives over mechanical methods to stick items together. These include:

- Can be easily applied. No drilling or expensive equipment required.

- The stress of the bond is more widely distributed along the joint.

- Allows for flexibility depending on the type of product used.

- Provides a cleaner finish compared to mechanical items like screws.

- Does not rust.

- Allows for more precise alignment of items.

- Can fill in gaps for a more even finish.

Drilling into any material can permanently damage it. If one item needs to be removed then there will be a hole which will require filling in. Sometimes special drill bits are required depending on the material. For example on tiles a special tile drill bit will be required.

It would be possible to attach a tile to the wall with screws and wall plugs but it won’t look very nice. Tile stuck onto the wall using a tile adhesive provides a much cleaner look.

In a similar way it’s also possible to attach wooden skirting to a wall with screws and wall plugs but the finish won’t be as good as an adhesive. In the image below, the skirting has been fixed to the wall with screws and wall plugs. The hole has then been filled in with wood filler but the finish is not similar to the natural wood.

Disadvantages of an adhesive over mechanical methods

There are some disadvantages to using adhesives compared to mechanical methods.

- Can be difficult to separate the items if access to the bond can not be reached.

- The bond can weaken over time.

- Products that are solvent based require good ventilation to apply.

- Solvent based products can attack sensitive materials.

- Can be difficult to clean.

- Some products can take a long time to dry. Temporary supports may be required.

- Chemicals can attack the bond to weaken it.

When using mechanical methods to attach two items together, using adhesives together with the mechanical method can further strengthen the joint.

How does an adhesive work?

The science of sticking

The aim of an adhesive is to resist the separation of two materials. Some products are stronger at doing this than others. The strength of a bond can also vary depending on the material surfaces it’s applied on.

Mechanism of bonding

For any adhesive to successfully create a strong bond between 2 items, they must wet the substrate, increase in strength as the product dries, spread the stress along the joint and maintain the strength of the hold as long as possible. There are two main forces at work, adhesion forces and cohesion forces.

Adhesive forces and cohesion forces

Imagine a water droplet on a car windscreen. Water drops naturally join together with other water drops to form larger water droplets. This is due to what water is made from, 2 hydrogen atoms and 1 oxygen atom. The forces that make the water drops do this is called cohesion forces.

Why do water drops cling onto the windscreen glass? The answer is because of adhesive forces. This sticking process is called adhesion. For the water drop to form into larger drops and cling onto the windscreen glass at the same time, both forces are at work at the same time and must be stronger than gravity. When the water drop becomes bigger, the weight increases due to the mass of the water and gravity. A point will come when the adhesion is not strong enough anymore to hold the water drop to the glass due to the increase in weight.

When the water runs down the windscreen glass, it will try to run down existing tracks of water. This is due to the cohesion forces that are trying to attract the water to other water rather than the glass. When the water starts running down, adhesive forces between the water and glass pull some of the water molecules away making small drops that cling to the glass again.

What makes a cohesive force?

In the above example with water, the water molecules attract to other water molecules because there is a difference is electrical charge at the 2 ends, they attract like magnets. One end has a positive electrical charge whereas the other has a negative electrical charge. This is called electrostatic bonding. Cohesive forces in water are quite weak compared to other materials.

Water would not make a good adhesive. This is due to the weak cohesive force in water. Paper can be stuck onto a surface by wetting it first with water but this can be peeled away very easily. It’s the weak cohesive force between the water molecules that would break easily.

What makes an adhesive force?

There are many different factors including:

- Adsorption

- Chemisorption

- Mechanical

- Diffusion

Absorption is when lots of little forces work together like electrostatic forces and van der Walls forces between the molecules of the adhesive and surface of the item. For an adhesive to work, it needs to wet the surface and spread thinly on the surface of the material.

Chemisorption is when an adhesive creates a chemical bond with the material they’re in contact with. This is a much stronger bond. An example is using a glue on certain plastics where the glue mixes with the plastic to create a new chemical compound. Sometimes this new compound can be stronger than the original plastic.

Mechanical is when the surface of the material is porous. A porous material has lots of tiny holes that allow the glue to go into the holes. Once the glue dries, the glue holds the material likes it grabbing it. Similar to how Velcro works.

Diffusion is when molecules from the material surface and glue swap molecules. This mixture of molecules holds the two items together once the glue dries.

History of adhesives

When were they first used?

Natural adhesives have been used for thousands of years by humans. These include birch-bark tar that was found covered over two stone flakes in central Italy, going back possibly 200,000 years ago. To produce birch-bark tar is a simple process as found in a study from 2019. It just involves burning birch bark near smooth vertical surfaces in the open air. These plant based adhesives can however be brittle and vulnerable to weather conditions. This type of product is called a one-component adhesive.

The earliest use of compound adhesives was in Sibudu, South Africa, possibly going back 70,000 years ago. This was a stone segment from an axe that was covered in plant gum strengthened in iron oxide. The iron oxide allowed the gum to perform a stronger bond and protected it from breaking in wet conditions.

Earlier examples

Egyptians

Studies at ancient burial sites have found tree resin used to repair broken clay pots dating back approximately 6000 years ago. Other examples include bituminous cements used to bond ivory to statues dating back 4000 BC. Adhesives first appeared in literature approximately 2000 BC. In Egypt several different types of adhesives have shown to used including animal based glue for bonding & lamination. Papyrus was bonded to clothing with starch based pastes. Other types of glue used by the Egyptians include milk protein based glues and calcined gypsum.

Greeks & Romans

The Greeks & Romans greatly developed adhesives between AD 1 to 500. Many different natural materials were used for different applications. Slake lime for mortar was used by the Greeks. The Romans improved the mortar further by adding sand and volcanic ash to the lime. Beeswax and tar was first used by the Romans to seal the wood on ships.

History of glue production

In the Netherlands, the worlds first commercial adhesive factory was established in 1960. Animal hides were used to produce glue in the factory. The first British patent for fish was issued in 1750. German and Swiss factories appeared shortly after producing casein glue. Casein glue was patented in the USA in 1876.

Postage stamps in the USA initially used starch based adhesives in 1847.

Modern adhesives

Rubber was first used as an adhesive from 1830. This marked the point for modern adhesives. Automobiles required stronger and more durable rubber to metal bonds. This helped push development of rubber that was treated with acids. This was developed further and by 1927 to produce solvent based rubber cements to bond metal to rubber.

Pressure sensitive adhesives first appeared in 1925. They were developed from natural rubber based sticky adhesives. Examples of applications include cloth backed surgical and electrical tapes.

Adhesives today

Adhesives are being used today in all sorts of different applications and items. Electronics, manufacturing, automotive, marine, dental, medical, food, products, signage and construction are just a few examples where adhesives are used. Each application requires a different type of product which will be discussed in the next section.

Importance of the market today

In almost every man made product, at least one adhesive is used. The demand for adhesive and glues is continuing to increase, especially in developing countries. As the world population goes up, the demand for consumer goods and construction needs will further increase the need for adhesives.

Types of adhesives

There are many different types of adhesives used today. These include:

- Pressure-sensitive (PSA)

- Anaerobic

- Contact adhesive

- Rubber-based

- Hot-melt

- Acrylic based

- Structural adhesives

- Cyanoacrylate

- Polyvinyl acetate (PVA)

- Polychloroprene adhesives

- Ultraviolet-cured

- Epoxy

- Polyurethane

- Silicon

- PMMA methyl methacrylate cements

- MS polymers

- Tile adhesive

- Phenolic

- Hybrid

- Cement

- Food adhesives

- Polyimide

- Medical and surgical

- Dental

- Solder

Pressure sensitive adhesive

Pressure sensitive adhesives are products that simply require pressure to stick to a material surface. They’re usually on one side of a tape type material. On double sided tape the adhesive is on both sides. The tape material is usually made from plastic but can also come in foam and rubber form. Other forms of pressure sensitive adhesives include a putty material, sticky tack (or blue tack which is a common brand). Generally the bond strength of pressure sensitive products is not strong compared to other types of adhesives. The advantage is they stick almost immediately and are fairly easy to remove and clean.

Anaerobic glue

Anaerobic glue is usually used for metal to metal joints. A typical example is for use on the thread of bolts and nuts to stop them from loosening, which can happen with vibration. This type of product is called a thread locker. Compared to other types of adhesives, it is a thinner consistency when first applied. This allows the products to works it’s way into gaps and fill them. It is mainly applied straight out of the bottle. Although anaerobic glues cure quickly, they’re usually slower than cyanoacrylate glues.

Contact adhesive

This type of product is usually applied with a brush or in spray form. They are typically used for larger surface area applications like on carpets, laminate, lino and other wooden surfaces. Contact adhesives are usually in solvent form or water form and dry when the solvent or water evaporates away. Contact adhesives are usually thinner and therefore have less gap fill properties than other products like MS Polymers.

Holt melt adhesive

Unlike most other types of adhesives, hot melt adhesives are initially solid. Usually they are bought in a stick form and require a special hot melt gun to apply. The applicator gun applies heats glue sticks to melt it for it to be able to apply to the material. Without this melting process, the adhesive would not be able to wet the surface of the material it needs to stick to. The stick starts to melt at about 79.4°C but the melted glue is applied at a higher temperature. The product simply needs to cool down for it to set hard so it dries very quickly. Basic crafts and DIY versions are available as well as professional versions for higher end applications.

Acrylic based

Acrylic based products can be used for a number of different construction applications however the final bond strength is usually lower than MS polymers. They are also more prone to cracking due to the bond being more brittle.

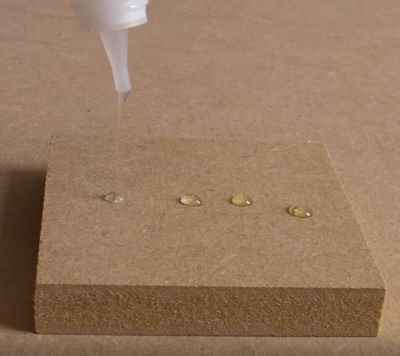

Cyanoacrylate

Also known as superglue, this type of product dries very quickly and provides a strong permanent bond. Some products can dry within 30 seconds however the bond can be brittle. They are usually runnier than other adhesives and are applied straight from the bottle onto the joint. It is mainly on smaller, more delicate applications that cyanoacrylate products are used on. They also have less gap fill properties than other products.

Polyvinyl acetate

Also known as PVA, this product has many different applications but usually used to stick wood. The bond is weaker and more brittle than other types of adhesives. PVA is used quite often in craft applications in schools and at home. It can also be mixed with water to create a sealing solution for use on items like plaster.

UV cured

As the name suggest, this type of product uses UV light for it to cure. It can provide a quick bond and is usually stronger than cyanoacrylate. It can however be more brittle compared to other types of adhesives. As this type of product requires UV light for it to cure, a UV light source is usually sold with it in a pack. Due to it’s thin consistency, it has less gap fill than other products.

Epoxy

Epoxy is a 2 component product. One component is a reactive agent also known as an epoxide. The second component is a hardening agent. Epoxies provide a very strong bond that is resistant to moisture, chemicals and corrosion. The product hardens when both components are mixed together. The product is sometimes available in two separate containers that require mixing. Sometimes the 2 containers are attached with a mixing nozzle that does the mixing when applying, making it easier to use. Not as flexible as MS polymer, they are however not as brittle as cyanoacrylate glues. Epoxies also tend to have a lot higher temperature resistance compared to other types of adhesives.

Polyurethane

Polyurethane needs moisture for it to dry. As it dries, it will usually expand making it a good product to use where high gap fill is required. High gap fill is required when the surfaces of the materials are not even. Polyurethane is also less brittle compared to most other products. Polyurethane is also available in a sprayable form (expanding foam) that can be used for insulation and filling cavities.

Silicon adhesive

Silicon is more likely to be used as a sealant but can also be used as an adhesive as well. The bond strength from silicon is usually lower than other products like MS polymers. Silicon provides good flexibility and have OK gap filling properties. They can provide waterproof joints. Silicon products are usually filled with solvents that require evaporating away for the silicon to dry.

MS Polymer

MS polymer is a versatile product that has many benefits over other types of adhesives. It can provide a high strength bond that is not brittle and have high gap fill properties. MS Polymers usually do not contain solvents but cure with moisture. Some MS polymer products can bond on wet surfaces.

Tile adhesive

Tile adhesive is a ready to use water based acrylic glue. It needs to have high initial grab to hold heavy tiles on vertical walls in place whilst the adhesive dries. To achieve this high initial grab, the adhesive is made thick by usually filling with other additives like cement, sand or other thickening agents.

Phenolic adhesive

This is available in a liquid form or in solid form. Phenolic adhesives with additives can resist very high temperatures and provide a very high strength bond. Depending on the product, they can cure in two main ways. One is called novolacs and the other called resoles.

Hybrid adhesive

This combines two or more different types to get the benefits of both. An example can be an epoxy with cyanoacrylate. The cyanoacrylate can provide a very quick bond whereas the epoxy part can provide a high strength bond that has high resistance to chemicals.

Cement

Mortar is regularly used in construction to bind bricks together and blocks together. Mortar is a mixture of sand, cement and water. Sometimes additives like lime or plasticiser are also used to adjust the properties of the mortar. Adhesion happens when the water evaporates away.

Food adhesive

There are many different types of adhesives used when making food items. Examples include using icing to stick items to a cake. Breadcrumbs stuck on chickens nuggets can be done several ways of which using eggs is one method. On samosas, the pastry is folded into a triangular to hold the filling in. To stop the triangle opening up, one end of the pastry is stuck on to another part of the pastry. This is usually done with an adhesive made from a mixture of flour and water. The adhesion happens when the water evaporates away. There are lots of other types food adhesives made from mixing different food items.

Polyimide

Polyimide can be available in several different forms. They have good high temperature resistance and good chemical resistance. They are used in many different applications including some high demanding industrial applications like in aerospace and electronics.

Medical and surgical

Adhesives are used in medical and surgical applications. Some examples include tissue adhesive or liquid stitches that are used to close wounds. There are advantages and disadvantages compared to using stitches or staples. Advantages include:

- No need to remove stitches

- Less scarring,

- Lower infection rates

- Quicker procedure

- No need for needles

- Quicker healing

Dental

Dental adhesives, also known as dental cements are used for securing teeth during restoration. Applications include fixing bridges, repair to crown and even building up a tooth where it has chipped. Dental adhesives need to be very durable due to the nature of where it is used. There are temporary and permanent versions available. Temporary products are used to hold temporary crowns in place. As these products are affected by saliva, they will need to be replaced with permanent dental adhesives within three to six weeks of application. Permanent products do not dissolve with saliva.

Denture adhesive are also used to hold dentures securely in place. They are made from non toxic materials and are applied between the denture and gums. The are available in 3 main version, paste, powder or strip. The powder version soaks up water and works in a similar way to the paste. The most common type available is the paste version. The strip version is more expensive compared to the other versions.

Solder

Solder is a metal alloy that is used to create a bond between metal. It is usually available as a coiled wire and is applied by melting it. The common method of melting solder is by using a soldering iron but gas torches are also used. The adhesion properties of the solder increases as it cools down. Good electrical conductivity solder is used to connect electrical wires. Another area where solder is commonly used is to attach copper pipe connectors together. This provides a good waterproof seal as adhesion properties.

Bond failure

Many different aspects can affect the bond strength of an adhesive. These can weaken the adhesion strength and eventually break the bond at the joint. These include:

- Temperature changes

- Sunlight (UV radiation)

- Vibration

- Chemical exposure like solvents

- Expansion & contraction

- Moisture

- Physical stress

Types of fracture

When physical stress is applied to a joint, the bond can break apart at different locations of a joint. Further stress can increase this break and travel along the joint. The main types of fracture include:

Cohesive fracture

This type of fracture happens in the bulk of the adhesive part of the joint. The adhesive still remains bonded to the surfaces of the materials they’re bonded to but the crack happens in the middle or near the middle of the joint. The chances of this type of cohesive fracture can increase if there is too much adhesive between the joint which can happen if not enough pressure has been applied to push the two material surfaces as close as possible.

Adhesive fracture

This type of fracture happens when the adhesive pulls away from at least one of the surfaces of the materials it’s bonded to. Some adhesives are purposely designed to operate this way. An example is sticky tape. When the sticky tape is pulled from the roll, the sticky residue is designed to remain on one side of the tape.

Another example is pulling a sticky label of an item. If no sticky residue is left on the surface then an adhesive fracture has taken place.

Mixed fracture

This is a combination of both cohesive fracture and adhesive fracture. In some place of the joint, the adhesive remains bonded to the material but separates in the adhesive itself. In other places the bond pulls away from the surface on the material it’s bonded to.

Alternating crack path

Similar to to the mixed fracture but the crack jumps from one side to the other.

Other bond failures

Some bond failures happen due to the material not being strong enough to resist the stress applied to it. Instead of the bond failing, the material itself can break away as the adhesion is stronger than the material. An example is sticking something to a painted wall. If the items falls off with the paint still stuck to the adhesive then the failure was due to the paint, not the adhesive. The adhesive was stronger than the substrate.

How to apply an adhesive

Depending on the application, the method to apply the adhesive changes. Common methods of applying adhesives include:

- Brush

- Roller

- Spray

- Films

- Applicator gun / sealant gun

- Direct from bottle, squeeze tube or container

To get a good quality bond, spreading the product thinly and evenly on as much surface area as possible is required. Pressure will be required to push both surfaces close together as possible. This pressure may need to be applied until the surfaces grab and don’t slide away. Temporary supports might be required as some products can take several hours or even days to fully dry.

Clean surface

The bond strength of any adhesive is only as strong as the strongest surface it is applied on. It is necessary to have a clean surface before applying the product. To get the strongest bond, remove any dust, grease, paint or any other dirt. Some surfaces are more likely to get dust than others. These include materials like stone and concrete. It is recommended to brush the surface. To thoroughly remove any fine dust, a finer brush like a painting brush should be used. Sometimes priming of the material may also be required. This will be discussed below.

Improve adhesion

For any adhesive to provide a good strong bond, it must be able to wet the surface area of the items being bonded to. This can be difficult on some materials that have lower surface energy compared to the surface energy of the adhesive. To be able to bond these materials, the surface requires treatment first to increase the surface energy. Some examples of surface treatment to increase surface energy include:

- Chemistry priming

- Flame treatment

- Plasma activation

Some materials that are difficult to bond include polypropylene, polyethylene, Teflon and other materials.

With Teflon designed to avoid things sticking to it, how does it stick to a pan? The answer is the surface of the pan is sandblasted first. This creates lots of small holes and cracks that allow an initial primer coat of Teflon to get into. Another layer of Teflon is then applied and baked at high temperature. The two layers polymerise with each other making the Teflon stick to the pan.

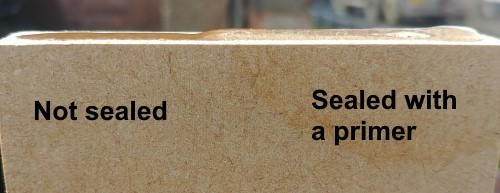

Priming

Some materials are porous and soak up liquids. This can be a problem when using liquid adhesives. The liquid adhesive can soak into the material before it cures, meaning little or no product will be left between the two surfaces of the joint. One of the main ways to stop a porous material from soaking up the liquid is to seal it with a primer. This allows the product to stay on the surface rather than penetrating into the material, creating a stronger bond. Materials that typically require priming include concrete, stone, fabric, MDF, brick and other materials.

In the above image, only the right hand side of the porous MDF has been sealed with a primer. A liquid glue was then applied all along the edge of the MDF. The liquid glue on the unsealed side has soaked into the porous MDF whereas the liquid glue on the sealed side has not soaked into the MDF. The sealed side will be able to create a much stronger bond than the unsealed side.

Products like Adiseal can work on porous materials even without the material needing sealing with a primer.

Safety

Due to the chemical make up of the different products, there are safety implications when using them. As some products contain solvents, good ventilation is required to use them. Personal protective equipment like face masks might be required. Hand protection like gloves may also be required to stop the chemicals attacking the skin. It is recommended to wash hands thoroughly with soap after use. Each manufacturer will have material safety data sheets (MSDS) for their products. Keep chemical products out of the reach of children.

Some products can attack the material they’re used on. Products that contain solvents can be aggressive on sensitive materials like polystyrene. Mirrors require special products like Adiseal, to stop them damaging the mirror backing.

Not all products are suitable for use in food preparation areas. ISEGA certified products are suitable for use in food preparation areas.

Adhesive removal

There are several ways to remove adhesives. Solvents can deactivate the bond on products that were made with solvents. These solvents usually have no affect on other types of products that were not solvent based. Mechanical removal might be the only option like cutting with a knife or thin wire. A chisel and hammer might be required to remove hard set products. Hot melt products can be deactivated with heat. Water can also be tried to help remove adhesives.

Adhesive and glue packaging

Why doesn’t the product stick to the tube or cartridge?

Adhesives and glues dry in different ways. They are designed so that they avoid drying and hardening in the packaging but start to cure once they come out of the packaging. Some products are filled with solvents. These solvents need to evaporate away for the the product to dry. This is also known as curing. Whilst the product stays in the tube unopened, there is no way for the solvent to escape.

Other products like epoxy require mixing with another chemical to activate the hardening process. These 2 component products are kept separate so that they don’t mix and harden in the packaging.

Products like MS polymers cure with moisture. When they are forced out of the packaging, moisture in the air starts the curing process. They will usually dry quicker on porous materials as the porous materials can absorb moisture in the air better than non porous materials.

The different between adhesive and glue

Both adhesives and glues have similar roles. They are designed to hold items together. There are several differences between them both but the main difference is the thickness of the products when their initially applied. Glues tend to be runnier whereas adhesives tend to be thicker when they’re first applied. This allows adhesives to have higher initial grab and gap fill than glues. Glues are usually used on smaller surfaces like sticking a broken ceramic handle back onto a ceramic cup. Adhesives are usually used on larger surfaces like sticking a ceramic tile to a wall with tile adhesive.

What to consider when choosing which product to use

There are many different factors to consider when choosing which adhesive to use.

Material

This is one of the most important points to consider when choosing which product to use. Will the adhesive stick to the material needing bonding? An adhesive may adhere very well to one material but not adhere well to the other. An adhesive needs to provide a good bond on both materials.

Cross sectional area

Does the material that require bonding have a good sized surface area to apply the adhesive. This can be more of a problem when sticking a round item to a flat surface. There will be little surface area between the two materials so only a small surface area will be available where the adhesive can be applied. For any application, the greater the surface area, the stronger the bond will be.

Drying time

How long does it take for the product to cure (to dry). Some products like super glues can set in seconds. Other products can take hours or even days to fully dry. Sometimes having a very quick drying time is disadvantageous as time might be required to align the two material surfaces in the correct place.

Initial grab

Once both surfaces have been pushed together with the adhesive in the middle, will the materials stay as they are? This tends to be a bigger problem when sticking heavy items to vertical surfaces like sticking something to a wall. If the initial grab of the adhesive is not strong enough then temporary supports may be required until the product dries. Some products like Adiseal Hi-Grab have very high instant grab to help avoid the use of temporary supports.

Solvents

If a product contains solvents, then good ventilation will be required when applying the product. Personal protective equipment might also be required like face masks. Solvents can also be aggressive and attack sensitive materials like polystyrene.

Shrinkage

There is a chance that products that contain something that need to escape from the product for it to cure will shrink as it’s curing. This is usually the case with products that contain solvents. That is because there is less active product in the tube. The problem with shrinkage is there is a chance the adhesive will pull away from the surface as it shrinks whilst it’s drying. This can leave a weaker bond than products that do not shrink.

Water resistance

How well will the adhesive perform when exposed to water? Some bonds might weaken or even break when in contact with water. Some product might not cure underwater.

UV resistance

How well will an adhesive cope with UV radiation from the sun? Some bonds can weaken with UV. Some products can even discolour over time with exposure to UV.

Bond strength

Is a product with the strongest bond required for all applications? Sometimes an adhesive with a weaker bond strength is more than capable for the application. There are times where a weaker bond strength is required rather than a stronger bond strength. An example is on a Post-it® note. The adhesive strength is only required to be strong enough to hold the Post-it® note paper to a surface. The bond strength needs to be weak enough to be able to pull the Post-it® note paper away easily without damaging the surface of the material it was stuck to.

The bond strength of an adhesive depends on the type and quality of a product. Independent adhesive strength test can show which is the strongest adhesive.

Temperature resistance

What is the temperature resistance of the adhesive. At higher temperatures, some bonds can weaken or even break apart. There is also a chance of the product catching fire at very high temperatures. In cold temperatures a bond can also weaken. Some products that are designed to stay flexible can harden at very cold temperatures.

Flexibility

How flexible will the product stay once it’s dried. Products that set hard can be brittle. With time these brittle bonds can develop cracks and weaken the bond. With temperature and air moisture changes, materials can expand and contract. Brittle bonds can break if they can’t move with this expansion and contraction.

Food safe

Are the products suitable for use in food preparation areas. Products that are suitable require certification like a ISEGA certificate.

Gap fill

What happens when the surfaces of the items being bonded are not flat? A thinner product may not be able to stay in the gap until the adhesive has fully dried. This would mean that when the adhesive has fully dried, it will leave places where there is no adhesive at all holding the two surface together. This will create a much overall weaker bond.

Chemical resistance

Will the adhesive be able to cope with contact with chemicals? Some chemicals can weaken and even deactivate a bond.

Adhesive failure

What are the safety implications if an adhesive fails? Any adhesive bond can weaken over time. Is it safe to stick a heavy item to a ceiling. The item might bond very well initially but what about the future if the adhesive fails. Could the item fall on someone?

Removal

How easy is it to break the adhesive bond when the items need to be separated. Once an item is removed and there is old adhesive left on a surface, how easy is it to remove. A solvent can deactivate and help remove some adhesives. Hot melt adhesives can be deactivated with heat.

VOC

Volatile organic compounds (VOC) can have a harmful effect on the environment. Products are better for the environment if they are low VOC. The lowest VOC products are certified EC1 Plus.

Staining

If porous materials soaks in the adhesive whilst it’s wet, there is a chance the adhesive will stain the product. This can be a problem on some natural stones that are porous.

Frequently asked questions about adhesives

An adhesive is a material that attaches two materials together. This method is different to using mechanical methods of holding items together.

This is not a straightforward answer. The answer depends on many different factors. Sometimes it’s better to use both mechanical fixings and adhesives together to further strengthen a joint.

Adhesion is the attraction between molecules of different substances, like water sticking to a glass surface. Cohesion is the attraction between molecules of the same substance, such as water molecules sticking together to form droplets. Both are crucial in natural and industrial processes.