Cable Lubricant

Cable Pulling Lubricant: Wire & Cable Installation Protection

CabLube cable pulling lubricant helps make wire and cable pulling easier during installation and also helps protect the cable from damage.

When installing cable, often the cable needs to be pulled through holes, conduit, ducting or trunking. A cable lubricant for pulling works by reducing the friction of the cable. It also makes installation of the cable a lot easier and speeds up the installation time, saving money on labour costs.

Why use cable pulling lubricant?

Cable is made up of several layers. Usually the conducting cores are near the middle. These conducting cores are usually covered by an electrical insulating material. On most cables, the conducting cores and it’s insulation is then protected further with an outer sheath. This outer sheath is usually made from flexible plastic material or sometimes rubber. On some cables there is added protection before the outer sheath. Steel wire armoured cable or SWA cable, has a steel wire covering before the outer sheath for extra protection. The diameter of SWA cable and it’s weight is a lot higher than other types of cable. This makes it harder to pull through conduit or ducting.

When pulling cable through conduit or ducting, the outer sheath can have high friction. This has the potential to damage the cable and insulation. If there is another cable already in the conduit or ducting, this increases the chances of damage. Using wire lubrication can reduce the chance of damage by reducing the friction of the cable.

Types of cable pulling lubricant

We have 3 different types:

- A gel form called CabLube Gel

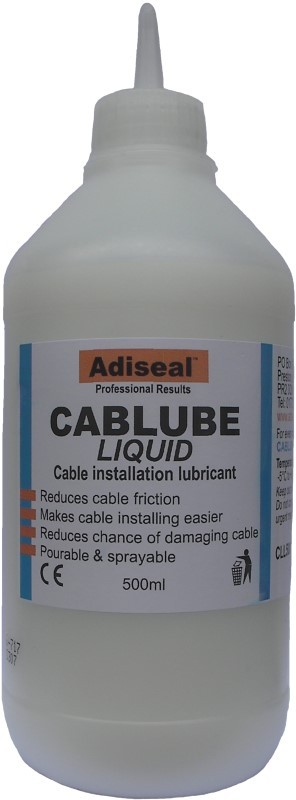

- A liquid version called CabLube Liquid

- An expanding foam version called CabLube Foam

CabLube Gel

A gel cable lubricant clings onto to the cable providing the highest lubrication and protection when pulling cables and wires through conduit. It is available in 500ml bottles but can be made in larger sizes on request.

Suitable for different types of cable and wire including power, control, instrumentation and control. It’s compatible with most common types of cable jacket materials. The lubricant is easy to apply and provides easy cleanup. The low solid contents means less chance of duct and conduit blocking.

- Appearance: Gel

- Odour: Slight characteristic

- Colour: Azure

- Viscosity: of about 26,000 cps

- pH: 7 to 7.2

- Operating temperature: -10°C to + 50°C

- Solubility: Soluble in water

CabLube Liquid

A pourable cable lubricant, designed to protect cable and wires from damage when being pulled through a conduit by reducing the friction. It is available in 500ml bottles but can be made in other sizes on request.

Suitable for different types of cable and wire including power, control, instrumentation and control. It’s compatible with most common types of cable jacket materials. The lubricant is easy to apply and provides easy cleanup. The low solid contents means less duct and conduit blocking.

- Appearance: viscous liquid medium

- Odor: Slight characteristic

- Colour: White transparent

- Viscosity: 52 sec. Ford Cup

- pH: 7 to 7.2

- Operating temperature: -5°C to + 50°C

- Solubility: Soluble in water

CabLube Foam

CabLube Foam is a 100% evaporating version that expands into conduit. It makes cable installation easier by reducing the friction and reduces the chance of damaging the cable. As CabLube foam is 100% evaporating, it does not block up the conduit or ducting. This foam version is available in 400ml aerosol cans.

Suitable for different types of cable & wire including power, control, instrumentation and control. It’s compatible with most common types of cable jacket materials. The lubricant is easy to apply and provides easy cleanup. Low solid contents means less duct & conduit blocking.

- Physical state: liquid in spray. Aerosols, foam is Dispensed.

- Colour: White

- Odour: Slightly of soap.

- Olfactory threshold. Not available.

- Ph: 8

- Melting point/freezing. 0°C.

- Relative density. 1 kg/l.

- Complete solubility in water.

- Boiling point 100°C

For electrical insulation gels please see our IPGel products.

How to use cable pulling lubricant

How to use cable pulling lubricant

- Prepare the Area

Ensure that the conduit or duct is clean and free of debris or obstructions. This will help prevent damage to the cable and ensure a smooth pull.

- Mix or Apply the Lubricant

Depending on the type of lubricant you have, you may need to mix it with water or apply it directly.

- Apply the Lubricant

There are a few methods to apply the lubricant:

Applicator: If you have an applicator, attach it to the conduit or duct. Feed the lubricant into the applicator and pump it through the conduit as you pull the cable.

Bucket or Container: If you don’t have an applicator, pour the lubricant into a bucket or container. Dip a clean cloth or sponge into the lubricant and generously apply it to the cable’s surface.

Hand Lubrication: Alternatively, you can apply the lubricant directly to the cable by hand, wearing gloves. Spread it evenly along the length of the cable. - Insert the Cable

Carefully insert the cable or wires into the lubricated conduit or duct. Ensure that the cable is properly aligned and doesn’t get tangled or kinked during the insertion.

- Pull the Cable

Use the appropriate cable pulling tools or equipment to gradually pull the cable through the conduit. The lubricant will reduce friction, making it easier to pull the cable.

- Monitor the Pull

While pulling the cable, keep an eye on the progress to ensure that it moves smoothly and doesn’t encounter any obstacles or tight spots.

- Clean Up

After successfully pulling the cable, wipe off any excess lubricant from the cable’s surface and the conduit opening. Properly dispose of any leftover lubricant as per local regulations.

Cable pulling lubricant MSDS

To download the MSDS, click on the links below for a PDF version.

Where to buy

To buy cable pulling lubricant in the UK, please contact us for details of your local stockist. For other countries that do not have a Adiseal distributors, you can buy from www.guglue.com

Frequently Asked Questions About Cable Pulling Lubricant

Adiseal CabLube Gel lubricant for pulling wire & cables provides the highest lubrication in our test.

Our products are suitable for different types of cable and wire including power, control, instrumentation and control cables. It’s compatible with most common types of cable jacket materials.

The Adiseal CabLube Foam provides 100% evaporation.

Cable pulling lubricant is used to make the cable pulling process smoother, preventing damage to cables, reducing the effort required, and facilitating faster installations.

Generally, they are not reusable. Once they are applied and used for cable installation, they should not be used again.

CabLube Gel is our best lubricant for cable pulling. It provides the highest lubrication and clings onto the cable. It is easy to apply and provides easy cleanup. It also has low solid contents so there is less blocking in conduit & ducting.