Concrete Adhesive

Strong Concrete Adhesive Bonding

Adiseal concrete adhesive provides a high-performance bond when sticking items to concrete and other materials. It provides a strong, flexible, durable and waterproof bond on concrete. Adiseal is suitable at sticking a variety of different materials to concrete both outdoors and indoors.

- What is the best adhesive on concrete?

- What is the best adhesive for wood to concrete

- How to attach wood to concrete

- How to bond metal to concrete

- What materials will Adiseal stick to concrete

What is the best adhesive on concrete?

There are many adhesive products capable of sticking items to concrete but they have very different performance. Adiseal construction adhesive sealant is our best adhesive for concrete bonding. It has been shown in independent testing to be the strongest adhesive for heavy duty bonding.

Independent adhesive strength test

In an independent adhesive strength test conducted by Ultimate Handyman, Adiseal was shown as over 3 times stronger than the next best product. Adiseal was so strong that even the screws of the test rig started to rip out, forcing the test on Adiseal to be abandoned.

| Product | Max pressure when adhesive bond broke (psi) |

| Adiseal | 3123 + psi |

| SupaBond | 1115 psi |

| Tec 7 | 1016 psi |

| HB42 | 942 psi |

| Loctite PL Premium | 873 psi |

| Gorilla Grab Adhesive | 862 psi |

| Bond It PU18 | 582 psi |

| Bond It Save Nails | 411 psi |

“That is actually unbelievable!”

Ultimate Handyman

Testimonials

Testimonials & some comments on the: Grab adhesive tests 2017, video on YouTube

- That Adiseal is phenomenal!

- That Adiseal is some stuff though, definitely need to get some of that bought!

- I instantly went looking for Adiseal!

- Need to get my hands on some of that to try out.

- Looks like a cracking product.

- Having used the two most expensive brands on numerous occasions, I’ll be trying out the others, especially the Adiseal.

- Adiseal certainly surprised me in this test!

- Fantastic tests. It’s unbelievable that Adiseal test with the hardwood.

Adiseal Adhesive & Sealant vs Adiseal Hi-Grab

Adiseal Hi-Grab construction adhesive also has higher gap-filling properties compared to Adiseal adhesive sealant. If you don’t require the extra high initial grab, the Adiseal adhesive sealant product is recommended for enhanced bonding.

What is the best adhesive for wood to concrete

Adiseal is our best adhesive for wood to concrete. It provides a strong, flexible, waterproof and durable bond between wood to concrete. It works with many different types of wood. Adiglue can glue wood to concrete for small applications but Adiseal adhesive sealant is more suitable for heavy duty wood to concrete bonding applications.

How to attach wood to concrete

How to attach wood to concrete

- Reduce gap

Minimise the gap between the wood and concrete surfaces. This can be done by cutting, filing, or sanding the surfaces to ensure an even contact area.

- Prepare the surfaces

Ensure both surfaces are clean, dry, and free from dust. We recommend brushing the concrete with a fine brush like a painting brush to remove fine dust.

- Apply the adhesive

Apply the adhesive then spread it evenly, covering the entire area where the wood will be attached.

- Position the wood

Position the wood onto the adhesive the apply firm and even pressure to ensure good contact between the wood and the concrete surface.

- Clean excess

Clean excess adhesive that may have squeezed out of the sides with a cloth and suitable cleaner. Once cured, this excess adhesive will need to be mechanically removed by cutting or breaking it.

- Secure the wood temporarily (optional)

If required, use clamps, heavy weights or other temporary supports to hold the wood in place while the adhesive cures.

- Allow the adhesive to cure

Give enough time for the adhesive to cure and avoid disturbing or putting stress on the bonded area during the curing process.

Tip: To store Adiseal once opened, leave about 1cm worth of product out of the nozzle and store the tube upright in a cool dry place. To re-use Adiseal, pull the cured part out or cut the nozzle until the uncured part is reached.

Cleaning concrete surface before applying the adhesive

For a high-quality adhesive bond on concrete or any other material, clean surfaces are essential prior to applying the adhesive. Dust, dirt or loose substrate can compromise the bond, particularly with concrete surfaces outdoors.

Concrete, especially in exterior bonding applications, can build up a layer of dirt which can be difficult to remove. To clean concrete thoroughly, consider options like jet washing or sandblasting. Alternatively, use a mixture of water and suitable detergent with a stiff brush, but note that jet washing is more thorough. If a detergent was used then ensure a thorough rinse with clean water to remove any residue before applying the adhesive. To remove fine dust from dry surfaces, you can use a vacuum, blower, or a fine brush, like a paintbrush. This preparation step before applying the adhesive is vital for a strong bond.

Concrete demonstration block

In the image above, we showcased various materials bonded to concrete using Adiseal. Unlike competitor adhesives, no primer or sealer was required on our concrete demonstration block. We simply cleaned the surface of the concrete block thoroughly before applying the adhesive.

How to bond metal to concrete

Surface preparation is vital for a strong bond on concrete. Remove oil, dirt, dust, and grease from both surfaces using Adisolve for stubborn deposits.

Lightly scratch the metal surface where adhesive will be applied (may not always be necessary) using fine-grit sandpaper or a file. Clean thoroughly afterward to remove loose metal particles. Apply adhesive between metal and concrete, pressing firmly.

Use temporary supports if items start to slide. Adiseal Hi-Grab adhesive provides even higher initial grab, reducing the need for supports in many cases. Allow sufficient curing time before removing temporary supports. Adiseal bonds to various metals including steel, iron, aluminum, copper, brass, lead, and more.

How to bond plastic to concrete

Adiseal bonds most plastics to concrete, except polypropylene, polyurethane, and polyethylene. Clean plastic thoroughly to remove dirt, oil, and grease. Increase bond strength by scratching the plastic surface. Apply adhesive and firmly press plastic onto concrete. Use temporary supports until adhesive cures. Allow sufficient curing time before removing supports.

How to bond rubber to concrete

Adiseal bonds natural rubber to concrete and various materials. Ensure clean surfaces for a quality bond. Apply adhesive to one surface, press rubber onto concrete firmly. Use temporary supports if needed until adhesive cures. Remove excess adhesive from edges before curing.

Please note Adiseal is suitable at bonding natural rubber but not synthetic rubber like neoprene.

How to bond stone, brick, tile or masonry to concrete

Adiseal is ideal for bonding stone, brick, tile, or masonry to concrete both indoors or outdoors. Surface preparation is vital to get a good strong bond.

Brush off dust before applying adhesive. No priming needed with Adiseal if surfaces are clean. Adiseal doesn’t bleed into porous stones.

Ensure clean surfaces, especially from loose bits and dust. Apply adhesive to one surface, press firmly onto concrete. Use temporary supports if sliding occurs.

Adiseal Hi-Grab is recommended for heavier items, reducing the need for temporary supports.

Effective for bonding various stone types including marble, granite, travertine, slate, ceramic, and more.

For extra safety with heavy stone, brick, tile, or masonry items, use mechanical fixings along with Adiseal, especially for vertical or overhead applications.

Glue for concrete

If you’re looking for a glue specifically designed for gluing materials to concrete, our Adiglue glue is a suitable option. While Adiglue offers greater flexibility and strength compared to super glues, it is still not as flexible or strong as our Adiseal construction adhesive & construction sealant.

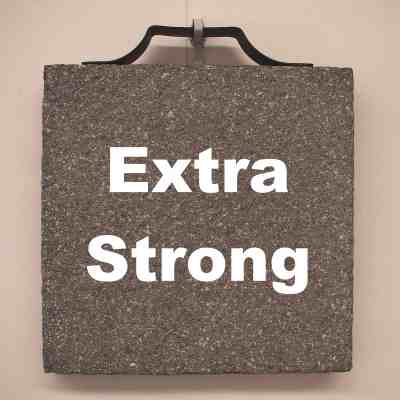

In the image above, we bonded a metal handle to a concrete slab with Adiglue. Before gluing, we sealed the concrete with Adiglue Activator to prevent glue absorption. However, Adiseal construction adhesive sealant doesn’t require concrete sealing for the same purpose.

Glue for concrete vs concrete adhesive

Whether a glue for concrete is better to use or a concrete adhesive depends on the type of job and the surface area available for the bond between 2 materials.

If you have to bond to concrete items with a small surface area then Adiglue is the better product.

If the items that needing bonding to concrete have a large surface area, then Adiseal adhesive & sealant or Adiseal Hi-Grab adhesive are the best products to use.

What materials will Adiseal stick to concrete

Adiseal will successfully bond the following materials to concrete:

Cement adhesive

Concrete and cement, while related, are distinct construction materials. Here’s the difference:

Cement is a powdered binding material made from limestone, clay, shells, silica, and other elements. It binds ingredients to form a solid mass, crucial in concrete production. Types include Portland cement, widely used in construction.

Concrete is a composite of cement, aggregates (like sand or gravel), and water. Aggregates provide strength, while water activates cement’s hydration. Upon curing, it hardens into a versatile material used in construction for foundations, walls, floors, and more.

Mechanical fixings

It is also possible to attach items to concrete by using mechanical fixings like screws. Adiseal Ultimate is the fastest no-hammer masonry drill bit and multi material drill bit. It is suitable at drilling concrete, drilling brick, wood and other building materials.

Colours

Adiseal adhesive and sealant is available in the following colours:

- White adhesive and white sealant

- Black adhesive and black sealant

- Grey adhesive and grey sealant

- Clear adhesive and clear sealant

- Brown adhesive and brown sealant

Adiseal can also be manufactured in any RAL colour.

Please note Adiseal adhesive sealant colours provide a stronger bond on concrete and other materials compared to the clear version.

Where to buy concrete adhesive

In the UK, to buy concrete adhesive, please contact us for details of your local Adiseal stockists. For other countries visit https://guglue.com/product-tag/concrete-adhesive/

Frequently Asked Questions About Concrete Adhesive

Adiseal is the best adhesive to stick items to concrete as it has proven to be the strongest adhesive by an independent adhesive strength test. Adiseal is extra strong, flexible, waterproof, has high gap fill, high grab, UV resistant and sticks almost any type of material to concrete without needing to prime the concrete.

As concrete is a porous material, it will soak up any liquid glue or adhesive. With Adiseal this is not required as Adiseal will not soak into the concrete. If the concrete does require sealing, use Adiglue Activator.

A concrete adhesive is a bonding agent used to join or bond concrete surfaces together. It works by creating a strong chemical bond between the adhesive and the concrete, providing enhanced strength and durability.

Yes, you can use Adiseal adhesive directly onto concrete surfaces for strong and reliable bonding.

Yes, construction adhesive, like Adiseal, forms a strong bond with concrete surfaces, providing reliable adhesion for various applications.

Adiseal is the perfect choice for sticking wood to concrete. It provides a strong, flexible, waterproof & durable bond between wood and concrete. Adiseal outperforms other adhesives in terms of bond strength.

Adiseal will provide a high strength bond when sticking stone to concrete. Adiseal provides a strong, flexible, waterproof & durable adhesive bond between stone and concrete.

When you have items to stick to concrete walls, Adiseal adhesive will provide a strong, flexible and waterproof bond between concrete and many other materials.