Marble Adhesive

Marble Adhesive: Adiseal Glue to Bond Marble, Granite, Stone

Adiseal marble adhesive forms a strong, flexible, waterproof bond on marble and other stones like granite. It doesn’t bleed into or stain porous materials like marble. Adiseal has high initial grab which can often eliminate the need for temporary supports, saving time and money on labour costs. Suitable for both interior and exterior use, Adiseal is also ideal for bonding marble tile and backsplashes due to its weatherproof properties.

- Why Adiseal is a great adhesive for marble

- How to bond wood to marble or granite

- How to stick marble or granite with adhesive

- Glue for marble or granite

Why Adiseal is a great adhesive for marble

Adiseal is a great adhesive for marble, granite, slate, limestone and other stone due to its record-breaking strength, flexibility, waterproof properties, and other key features:

- Unmatched strength: Adiseal has undergone independent testing and proven to be the strongest adhesive and sealant available.

- Flexible and durable: It maintains flexibility to accommodate vibrations and movements without weakening or becoming brittle.

- Waterproof performance: Adiseal is fully weatherproof & waterproof, making it suitable for both indoor and outdoor applications, including underwater use.

- Adiseal requires no priming, saving time and money as long as the surface is clean.

- Non-staining formula: Adiseal won’t stain or bleed into marble, granite, stone, or other porous materials, preserving their appearance.

- Excellent gap-filling properties: Even on uneven surfaces, Adiseal provides high gap fill capabilities for a strong bond allowing good marble gap join.

- Strong initial grab: Adiseal offers a high initial grab, reducing the need for temporary supports during the curing process. Adiseal Hi-Grab is available for more demanding applications where even higher initial grab is required.

- Adiseal is certified ISEGA, making it safe for food preparation areas. It’s ideal for use on marble countertops, sinks, and backsplashes in kitchens.

Performance

In our demonstration, we bonded marble to concrete using solvent-free Adiseal adhesive, achieving a strong bond without surface sealing. Adiseal adheres to porous surfaces without bleeding or staining. Dust was brushed off the concrete with a painting brush before applying the adhesive.

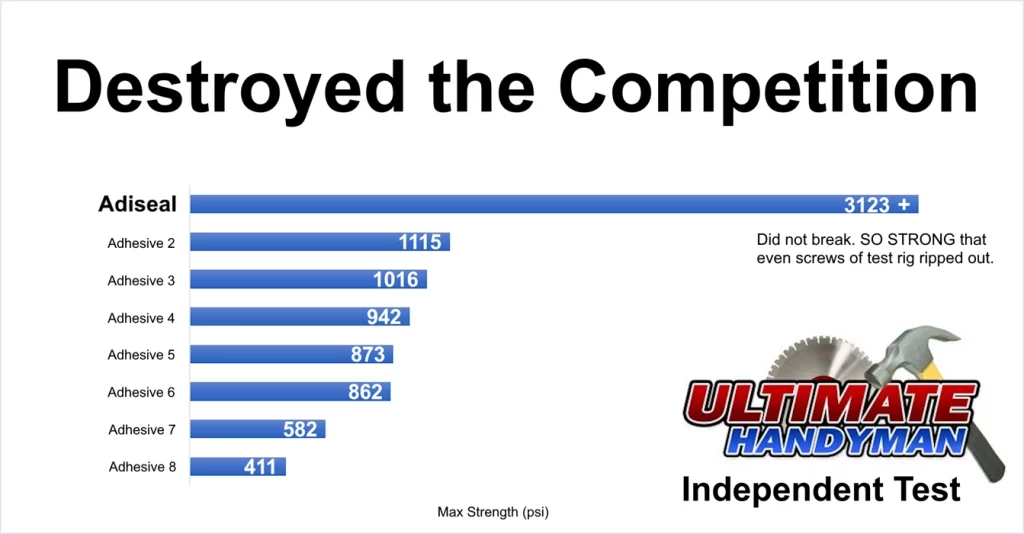

Strongest adhesive in independent test

In an independent adhesive strength test, Adiseal exceeded its nearest competitor’s strength by over three times. The test on Adiseal was halted at 3123 psi when the screws securing the rig began to tear out, indicating Adiseal could have performed even better. The other adhesives in the test failed at 1115 psi or below. The table below shows the results of the test.

Adiseal Adhesive Sealant vs Adiseal Hi-Grab

For an adhesive with higher strong initial grab, consider Adiseal Hi-Grab. It provides an even stronger initial grab than the standard Adiseal adhesive sealant, making it perfect for heavy-duty applications or scenarios where temporary supports cannot be used during the curing process. Both Adiseal adhesive sealant and Adiseal Hi-Grab offer comparable final bond strength but for most adhesive applications, we recommend using the Adiseal adhesive sealant product. Due to the thick nature of the Adiseal Hi-Grab adhesive, pushing items close together requires a lot higher force.

The image below shows Adiseal Hi-Grab’s superior initial grab, tested on the edge of heavy concrete blocks. We applied the product to the thin edge of one block and immediately attached it to the other block, demonstrating its superior initial grab.

How to bond wood to marble or granite

Adiseal creates a strong bond between wood and stone like marble. It is suitable for both indoor and outdoor use. Before applying the adhesive, clean surfaces thoroughly before application, using a fine brush for dust. Apply the adhesive, press firmly, and use vertical strips in damp areas to prevent water buildup on top of the adhesive. In cold conditions, watch for water freezing, which can weaken the bond. Temporary supports may help if sliding occurs, with curing taking around 48 hours. A flexible adhesive accommodates wood expansion without compromising the bond.

For added safety when bonding heavy wood or marble items in vertical or overhead applications, it is recommended to use mechanical fixings along with an adhesive.

How to bond metal to marble or granite

To bond metal to marble or granite effectively with Adiseal, follow these steps:

- Ensure both surfaces are clean.

- Some metals may have an oil coating; remove it with Adisolve, effective against oil, grease, tar, and stubborn residues.

- For a stronger bond (though not necessary), lightly scratch the metal where the adhesive will be applied, then clean to remove loose metal particles.

- Apply the adhesive and firmly press the metal to the marble. Use temporary supports if needed or consider using Adiseal Hi-Grab adhesive for enhanced grip.

- For safety with heavy metal items in vertical or overhead applications, use mechanical fixings alongside the adhesive for a secure and reliable bond.

These steps ensure a reliable bond between metal and marble using Adiseal.

How to bond plastic to marble or granite

To bond plastic to marble or granite using Adiseal, follow these steps:

- Clean the plastic surface thoroughly to remove dust, oil, grease, paint, or dirt.

- While it’s optional, lightly scratching the plastic can enhance the bond strength (not required).

- Note that Adiseal is suitable for some plastics like PVC but not for others such as polypropylene and polyethylene.

- Apply Adiseal to either the plastic or marble surface.

- Press the plastic firmly onto the marble. Use temporary supports if there’s any movement.

- Allow up to 48 hours for Adiseal to fully cure.

This process ensures a strong bond between plastic and marble using Adiseal.

How to stick marble or granite with adhesive

How to stick marble or granite with adhesive

- Prepare the surfaces

Ensure that both the marble / granite surface and the surface you want to bond it to are clean, dry, and free from dust, dirt, grease, or any other contaminants.

- Apply the adhesive

Apply a thin, even layer of adhesive to either the marble, granite or to the surface you want to bond it to. Covering as much surface area as possible provides better and stronger adhesion. You can use a brush or a suitable applicator to spread the adhesive evenly.

- Press and hold

Carefully align the marble / granite piece with the target surface and firmly press it into place. Apply even pressure across the entire surface to ensure a strong bond. Hold the marble / granite in place for a few moments to allow the adhesive to start bonding.

- Cure time

Follow the instructions provided by the adhesive manufacturer regarding the recommended curing time. Adiseal typically takes around 24-48 hours to fully cure, but the exact time may vary depending on factors such as temperature and humidity. Use temporary support if necessary.

- Avoid movement

Avoid disturbing or putting stress on the bonded marble / granite during the curing process. This will help ensure a strong and durable bond.

For safety when bonding heavy materials like marble, granite, or brick, it’s recommended to use mechanical fixings alongside adhesive for vertical and overhead applications. This dual approach enhances stability and reduces the risk of detachment.

Tip : In wet environments, apply adhesive in thin vertical strips to allow water to drain between them and prevent pooling. This reduces the risk of water freezing and exerting extra pressure on the adhesive.

Glue for marble or granite

Adiglue can be used to glue marble, granite or other stones, but it is not as flexible or strong as Adiseal adhesive sealant or Adiseal Hi-Grab adhesive.

In the example below, a metal handle was glued to a concrete slab using Adiglue, with the surface sealed by Adiglue Activator. However, when using Adiseal or Adiseal Hi-Grab adhesive for metal-to-concrete, marble, or granite bonding, sealing of porous materials is not necessary.

Colours

Adiseal adhesive and sealant is available in the following colours:

- White adhesive and white sealant

- Black adhesive and black sealant

- Grey adhesive and grey sealant

- Clear adhesive and clear sealant

- Brown adhesive and brown sealant

Adiseal can also be manufactured in any RAL colour.

Where to buy marble adhesive?

In the UK to buy marble adhesive or marble glue, please contact us for details of your local stockist. For other countries visit www.guglue.com

Frequently asked questions about marble adhesive or glue

Adiseal adhesive sealant is our best adhesives for marble. It provides a strong, flexible, waterproof and durable bond on marble.

No, Adiseal does not stain or bleed into marble or other porous materials, ensuring a clean and neat appearance.

Marble is a porous material that requires an adhesive with strong bonding properties and compatibility with its surface.

No, not all adhesives are suitable for bonding marble. It’s crucial to choose an adhesive specifically formulated for marble applications. Some products will bleed into and stain the marble.

Yes, marble can be effectively glued using specialised adhesives such as marble adhesive or glue. These adhesives provide a strong and durable bond for marble surfaces.

Adiseal adhesive has been shown to be the strongest product in an independent adhesive bond strength test. It also provides a flexible, waterproof and long-lasting bond on granite or marble.

Tile adhesive is normally used to stick ceramic tiles to brick or plaster on a wall but may not be suitable at adhering to smooth marble. Adiseal adhesive sealant provides a strong, flexible, waterproof and durable bond between tile and marble.

Most adhesives and glues require porous materials like marble or concrete to be sealed before application of the adhesive or glue. This stops liquid products from bleeding into the substrate and staining it. Adiseal adhesive sealant provides a strong, flexible, waterproof and durable bond between marble and concrete without the need to seal the substrate first.