PVC Adhesive

PVC Adhesive Glue: Strong, Flexible, Waterproof & Durable

Adiseal PVC adhesive provides a high-strength and flexible bond on many different PVC items. It will glue PVC items to many different materials, providing a strong, durable, waterproof and flexible bond on PVC wall panels, PVC cladding, PVC trim, PVC sheets, shower panels, or other PVC items. Adiseal PVC adhesive glue has many advantages over other products when it comes to sticking PVC.

- Why Adiseal is a great adhesive for PVC

- How to use a PVC adhesive

- What are the PVC items it can bond

- Where to buy PVC adhesive

Why Adiseal is a great adhesive for PVC

Adiseal adhesive offers numerous benefits when it comes to bonding PVC materials. One of the standout features of Adiseal adhesive is its exceptional bond strength, as proven by independent tests conducted by Ultimate Handyman. It has been demonstrated to be the strongest construction adhesive available, ensuring a robust bond between PVC and other materials. As well as Adiseal being a great PVC joint adhesive, it is also a great PVC joint sealant providing a high quality waterproof seal.

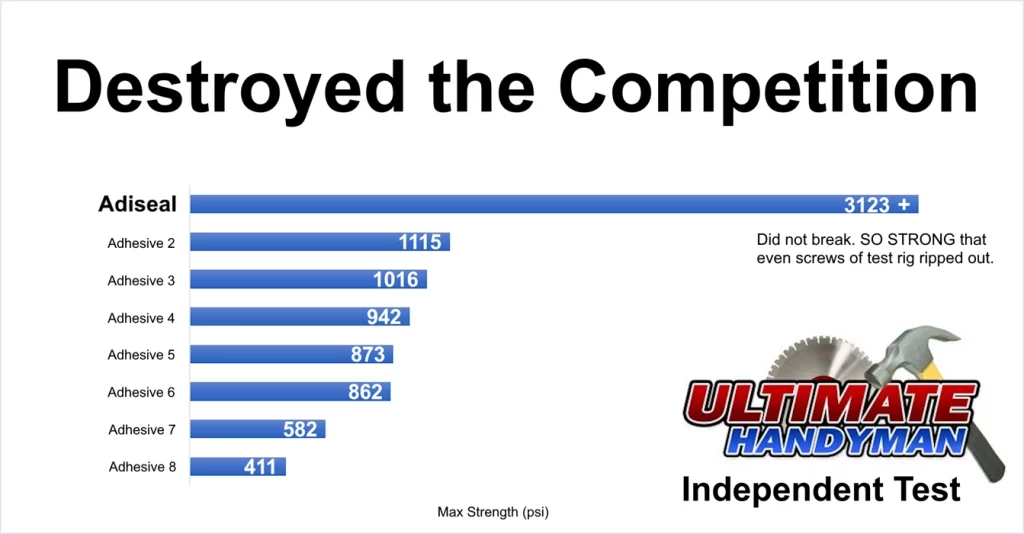

Adiseal Strength Test

In an independent adhesive strength test conducted by Ultimate Handyman, Adiseal displayed extraordinary strength, surpassing its closest competitor by more than threefold. During the test, the exceptional strength of Adiseal was evident as the screws securing the test rig started to tear out, leading to the test being halted. Even at a pressure exceeding 3123 psi, Adiseal remained intact and steadfast, showcasing its unmatched strength and durability whereas all the other adhesive bonds in the test broke at 1115 psi or lower.

Best adhesive strength test results table

| Product | Max pressure when adhesive bond broke (psi) |

| Adiseal | 3123 + psi |

| SupaBond | 1115 psi |

| Tec 7 | 1016 psi |

| HB42 | 942 psi |

| Loctite PL Premium | 873 psi |

| Gorilla Grab Adhesive | 862 psi |

| Bond It PU18 | 582 psi |

| Bond It Save Nails | 411 psi |

“That is actually unbelievable!”

Testimonials

Testimonials & some comments on the: Grab adhesive tests 2017, video on YouTube

- That Adiseal is phenomenal!

- That Adiseal is some stuff though, definitely need to get some of that bought!

- I instantly went looking for Adiseal!

- Need to get my hands on some of that to try out.

- Looks like a cracking product.

- Having used the two most expensive brands on numerous occasions, I’ll be trying out the others, especially the Adiseal.

- Adiseal certainly surprised me in this test!

- Fantastic tests. It’s unbelievable that Adiseal test with the hardwood.

Benefits of Adiseal

Materials it can bond

Adiseal Adhesive & Sealant vs Adiseal Hi-Grab

The Adiseal adhesive sealant product exhibits a strong initial grab, but for an even greater level of grab, the Adiseal Hi-Grab adhesive is recommended. Both construction adhesives offer comparable final bond strength. For most PVC bonding applications, the Adiseal adhesive sealant product is recommended. The reason for this is because the Adiseal Hi-Grab is a thicker product which requires a lot higher force to push items close together when attempting to bond.

How to use a PVC adhesive

How to use PVC adhesive

- Surface Preparation

Clean the surfaces you intend to bond with the adhesive. Remove any dirt, dust, grease, or loose particles using a suitable cleaner or solvent. Ensure the surfaces are dry before proceeding.

- Application

Apply the PVC adhesive to one of the surfaces. Follow the manufacturer’s instructions regarding the amount of adhesive to use. Be cautious not to apply an excessive amount that could result in excessive squeeze-out or messiness.

- Spreading

Use a brush or applicator to spread the adhesive evenly over the surface. Ensure the adhesive covers the entire bonding area uniformly.

- Joining the Surfaces

Press the two PVC surfaces together firmly, aligning them properly. Apply pressure to ensure good contact between the adhesive and the surfaces. If needed, use clamps or other suitable methods to hold the materials in place while the adhesive cures.

- Curing Time

Allow sufficient time for the adhesive to cure. Keep in mind that curing time can vary based on factors such as temperature, humidity, and adhesive type.

- Clean-Up

Clean any excess adhesive immediately using a suitable solvent or cleaner. Be careful not to disturb the bonded surfaces during this process.

Tip: To store Adiseal once opened, leave about 1cm worth of product out of the nozzle and store the tube upright in a cool dry place. Adiseal requires moisture for it to cure. The exposed part out of the nozzle will cure creating a cap. To re-use Adiseal, pull the cured part out or cut the nozzle until the uncured part is reached.

What are the PVC items it can bond

Adiseal can effectively bond and provide a strong hold to a wide range of PVC items. Here are some examples:

- PVC wall panels

- Shower wall panels

- Cladding

- Panels

- Trim

- Sheet

- Trunking

- Conduit

- Moldings

- Skirting

- uPVC trim

- Adhesive for PVC bathroom cladding

- Electrical boxes

- Plus many more PVC construction materials

The versatility of Adiseal adhesive & sealant makes it a reliable option for bonding various types of PVC items, providing a long-lasting and durable hold.

Colours

Adiseal adhesive and sealant is available in the following colours:

- White adhesive and white sealant

- Black adhesive and black sealant

- Grey adhesive and grey sealant

- Clear adhesive and clear sealant

- Brown adhesive and brown sealant

Adiseal can also be manufactured in any RAL colour.

Best adhesive for PVC wall panels & PVC bathroom cladding

Adiseal is an ideal adhesive for PVC wall panels and our best adhesive for PVC bathroom cladding, offering exceptional strength, waterproof properties, and flexibility. It can effectively bond PVC panels and PVC bathroom cladding to various surfaces like brick, concrete, plaster, wood, stone, tile, marble, and more.

In wet areas, it is recommended to apply Adiseal in thin vertical strips, especially in areas where water may seep behind the wall panels. This prevents water accumulation on top of the adhesive behind the PVC panel, which can freeze, expand and cause added pressure on the bond during cold temperatures.

Best adhesive for uPVC trim

Adiseal is a great adhesive to stick uPVC trim. It will glue uPVC trim to various building materials when installing windows or other construction applications. It will provide a strong, flexible, waterproof and highly durable bond.

PVC glue

Adiglue can be used to glue PVC, but it should be noted that it is not as flexible or strong as Adiseal construction adhesive & construction sealant. While Adiglue is less brittle than super glues, it may not provide the same level of flexibility and strength.

Where to buy PVC adhesive

To buy PVC adhesive in the UK, please contact us for details of your local stockist. For other countries that do not have a Adiseal distributor, you can buy from www.guglue.com

Mechanical fixing

It’s also possible to use a PVC adhesive together with mechanical fixings like screws to further strengthen the attachment between the PVC item and the other material. Adiseal Ultimate metal drill bit is a great product to drill PVC and other materials. Adiseal Ultimate masonry multi-material drill bit is also a good product to drill into PVC and other materials but the metal drill bit provides a cleaner drilled hole.

Frequently asked questions about PVC adhesive

Adiseal is the best adhesive for PVC as it has proven to be the strongest adhesive by an independent adhesive strength test. Adiseal is flexible, waterproof, high gap fill, high grab, UV resistant and sticks almost any type of material to PVC.

To remove PVC adhesive, it is best to use a sharp item such as a knife or chisel. Chemical adhesive removers are generally not effective in removing PVC adhesive or may even damage the material. Be careful when using sharp tools to avoid damaging the surface of the PVC.

Adiseal adhesive & sealant is a waterproof product that can glue PVC and many other materials. It works in the dry, damp, wet & even underwater.

PVC adhesive can bond to various surfaces, including wood, metal, concrete, plastic, tile, cable, polystyrene, masonry, glass, marble, and many other materials.

Yes, there are PVC adhesives available that are suitable for outdoor use. Look for adhesives with waterproof properties and the ability to withstand weather conditions.

In many cases, priming is not necessary as long as the surface is clean and free from dirt, grease, or paint. However, it’s always recommended to check the adhesive’s instructions for specific surface preparation requirements.

Yes, Adiseal adhesive provides a high quality, strong, waterproof and durable bond on PVC that also remains flexible.

Adiseal Hi-Grab adhesive provides a strong, flexible, waterproof and durable bond on PVC cladding. It has the additional advantage of extra high initial grab, gripping the PVC and allowing for precise adjustment without the cladding slipping during the curing stage of the adhesive.

Adiseal Hi-Grab adhesive provides a strong, waterproof, flexible and durable bond when sticking PVC to plaster, plasterboard, concrete, brick, cement, stone, tile or many other substrates. It has the additional advantage of extra high initial grab, gripping the PVC and allowing for precise adjustment without the cladding slipping during the curing stage of the adhesive.