Flexible Adhesive

Flexible Adhesive: Elastic, Stretchable, Bendable & Strong Bond

Adiseal flexible adhesive provides a strong and durable bond on many materials. Due to its flexible bonding, Adiseal is more durable than non-flexible adhesives or glues. Its adhesive bond remains elastic, stretchable, bendable and non-brittle, absorbing material movement without the bond weakening. Adiseal has also been shown to be the strongest adhesive in an independent adhesive strength test.

- Why use a flexible adhesive?

- What is the best flexible adhesive?

- How to use a flexible adhesive

- Extra strong adhesive for many different materials

- Where to buy flexible adhesive

Why use a flexible adhesive?

- Temperature changes

- Vibration

- Moisture changes

- Wind

- Knocks

- Sound

- Expansion

- Contraction

Non-flexible adhesives and glues become brittle as they harden, which raises the risk of adhesive failure. A brittle glue or adhesive bond is prone to cracking, weakening over time, and eventually failing. In contrast, an adhesive that remains elastic, stretchable and flexible glues can absorb stresses and joint movement without cracking, resulting in a more durable resilient bond. They can accommodate the stresses placed on the adhesive without it becoming weak.

Problems of using the wrong adhesive

Using a glue or adhesive without flexibility, when a flexible one is needed, can lead to various problems:

- Lack of Joint Movement Accommodation: Non-flexible adhesives and glues harden and become brittle, unable to withstand movement or stress, compromising the bond over time, potentially resulting in cracks, delamination, or failure.

- Structural Issues: When bonding materials with different expansion coefficients, like metal and plastic, they cannot adapt to varying rates of expansion and contraction, causing gaps, leaks, or disintegration.

- Inability to Withstand Environmental Factors: Non-flexible adhesives and glues may not endure environmental conditions like temperature fluctuations, moisture, or vibrations. This can worsen the rigidity of the adhesive, leading to premature bond failure and potential assembly damage.

Choosing the right adhesive or glue that matches the specific application requirements is crucial for ensuring lasting, reliable results. Using an adhesive with stretchable elastic bonding in the video below could have prevented the bond failure experienced with the non-flexible adhesive.

What is the best flexible adhesive?

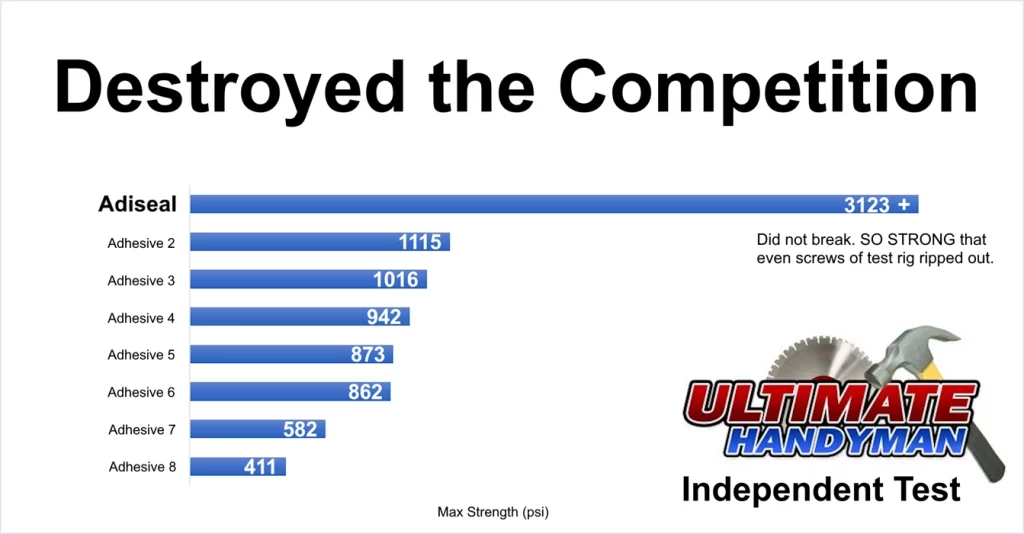

To find out the strongest and best adhesive, Ultimate Handyman conducted a series of adhesive strength tests. The results were nothing short of impressive. Adiseal emerged as the indisputable best adhesive, demonstrating unparalleled strength that far surpassed all other competitor products. In fact, no other adhesive even came close to matching the incredible adhesive power of Adiseal with it being over 3 times stronger than the nearest competitor. Witness the astonishing test yourself in the video below.

The best adhesive was Adiseal

Strongest adhesive strength test results table

“That is actually unbelievable!”

Ultimate Handyman

Testimonials

- That Adiseal is phenomenal!

- That Adiseal is some stuff though, definitely need to get some of that bought!

- I instantly went looking for Adiseal!

- Need to get my hands on some of that to try out.

- Looks like a cracking product.

- Having used the two most expensive brands on numerous occasions, I’ll be trying out the others, especially the Adiseal.

- Adiseal certainly surprised me in this test!

- Fantastic tests. It’s unbelievable that Adiseal test with the hardwood.

How to use a flexible adhesive

How to use a flexible adhesive

- Surface Preparation

Ensure that the surfaces to be bonded are clean, dry, and free from any dirt, dust, grease, or contaminants. Clean the surfaces thoroughly using an appropriate cleaner or solvent if necessary.

- Application

Apply the product evenly to one of the surfaces using a suitable applicator.

- Bonding

Align the surfaces to be bonded and carefully press them together, applying firm and even pressure. Make sure the adhesive spreads evenly between the surfaces, ensuring maximum contact.

- Curing Time

Allow the adhesive to cure as per the manufacturer’s instructions. This typically involves giving it sufficient time to dry and develop a strong bond. Keep in mind that curing times can vary depending on the type of adhesive used, environmental conditions, and the materials being bonded.

- Clean-Up

Remove any excess adhesive immediately using a suitable solvent or cleaner recommended by the manufacturer.

- Post-Cure

After the initial curing period, it is advisable to allow additional time for the adhesive to fully cure and reach its maximum strength. This may involve keeping the bonded item in a stable environment with optimal temperature and humidity conditions.

Tip: To store Adiseal once opened, leave about 1cm worth of product out of the nozzle and store the tube upright in a cool dry place. Adiseal requires moisture for it to cure. The exposed part out of the nozzle will cure creating a cap. To re-use Adiseal, pull the cured part out or cut the nozzle until the uncured part is reached.

Extra strong adhesive for many different materials

Adiseal flexibility demonstration

The video shows the flexibility of Adiseal adhesive sealant once it is cured.

Flexible PVC adhesive

Adiseal is a robust and flexible adhesive perfect for PVC and other plastics, delivering strong bonds with PVC materials. Note that it may not be suitable for certain plastics like polypropylene, polyurethane or polyethylene. For maximum bond strength, thorough surface cleaning is essential. Adiseal is an excellent option for applications like PVC cladding, PVC trunking, PVC pipes, and other items demanding a robust and flexible PVC adhesive solution.

Flexible wood adhesive

Adiseal is exceptional as both a PVC and wood adhesive, forming strong stretchable elastic bonds on various wood types, demonstrating its versatility in woodworking. For optimal bond strength, thorough cleaning of wood surfaces before applying the adhesive is essential. This step guarantees Adiseal’s durable and reliable bond, instilling confidence in any wood bonding project.

Adiseal Applications and Benefits

- Works in dry, wet, even underwater

- Best grab (for even higher grab use the Adiseal Hi-Grab adhesive)

- Waterproof sealant

- Waterproof adhesive

- Fast power grab and bond grip

- Gap filler adhesive

- Resists mould

- Over paintable (with most paints)

- Non brittle (stays flexible)

- UV resistant

- Virtually odourless (no harsh smell)

- Isocyanate free

- Solvent free (safe for sensitive materials)

- No shrinkage or cracking

- Flexible sealant and adhesive

- Prevent fungal growth

- Prevent bacteria growth

- Good resistance to chemicals

- Indoor and outdoor suitable

- EC1 Plus certified (no VOC)

- ISEGA certified – safe for use in food preparation areas

Colours

Adiseal adhesive and sealant is available in the following colours:

- White adhesive and white sealant

- Black adhesive and black sealant

- Grey adhesive and grey sealant

- Clear adhesive and clear sealant

- Brown adhesive and brown sealant

Adiseal can also be manufactured in any RAL colour.

Where to buy flexible adhesive

In the UK, to buy flexible adhesive, please contact us for details of your local stockists. For other countries, Adiseal products can also be purchased from https://guglue.com/product-tag/flexible-adhesive/

Frequently asked questions about flexible adhesive

In an independent adhesive strength test, Adiseal was found to be the best adhesive. It was a lot stronger than all the other products that were tested. In the wood to metal adhesive strength test, Adiseal flexible adhesive was way stronger than anything else tested.

Flexible adhesives offer several advantages, such as accommodating joint movement, preventing cracks or failures, providing resilience in varying conditions, and maintaining bond strength over time.

Flexible adhesives can bond a wide range of materials, including plastics, metals, wood, rubber, fabric, and more.

Yes, many products are designed to withstand outdoor conditions, including exposure to sunlight, moisture, and temperature fluctuations.

To achieve a strong bond, it is important to ensure both surfaces are clean, dry, and free from contaminants. Following the manufacturer’s instructions regarding application thickness, curing time, and surface preparation is crucial.

Some products may not be suitable for bonding certain materials, such as polypropylene or polyethylene. It is important to check the manufacturer’s guidelines for compatibility with specific materials.

A flexible adhesive is required when there is potential movement in the material being bonded. Materials naturally move due to a number of factors like temperature or moisture changes. Non-flexible adhesive set hard and brittle, which can weaken or even break over time due to the movement. An adhesive that remains flexible has elastic properties to allow it to stretch and bend without the bond becoming weak.