Roofing Felt Adhesive

Roof Felt Adhesive: Adiseal Bond & Seal on Roof or Shed

Adiseal roof felt adhesive glue provides a strong, heavy duty, durable bond on roofing felt to various building materials including timber, concrete, metal, shed and brick. It is solvent-free and a cold applied roofing felt adhesive glue, making it safer to apply as no gas torch is required. As well as being a roofing adhesive glue, Adiseal also provides a watertight seal, increasing the waterproof properties of the roof or shed. Adiseal can bond and seal the roof or shed in dry, damp or wet conditions. It can seal instantly making it ideal for emergency repairs as well as permanent long term fix.

- Why use Adiseal roofing felt adhesive

- Can it seal in wet conditions

- How to apply roofing felt adhesive

Why use Adiseal roofing felt adhesive

Adiseal roof felt adhesive glue combines strong heavy duty bonding, flexibility, durability, and sealing properties, even in rainy conditions. It creates a long-lasting, weather-resistant bond, capable of withstanding temperature changes and structural shifts.

What sets Adiseal apart is its versatility and reliability. It adheres easily to various surfaces, including brickwork, masonry, concrete, wood and metal, making it suitable for diverse roofing applications, whether flat, pitched, or vertical. Adiseal ensures a secure, watertight seal for optimal performance.

Moreover, Adiseal excels in preventing water penetration, providing robust protection for your roof or shed, even during heavy rain. This exceptional feature reduces the risk of leaks, safeguarding your structure and valuables from potential damage.

Can it seal in wet conditions

Adiseal is able to seal a leak on roof felt or shed instantly, even in wet conditions like rain. This makes it ideal for carrying our emergency repairs in the rain. Check out our demonstration of Adiseal sealing a leak underwater.

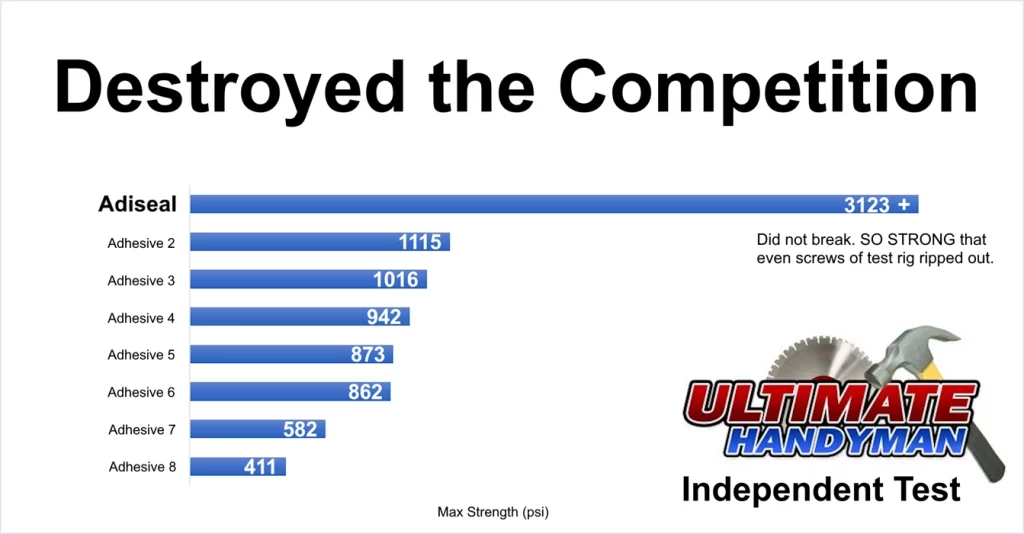

Strongest adhesive

In an independent adhesive strength test by Ultimate Handyman, Adiseal heavy duty adhesive blew away the competition. Nothing came anywhere close to Adiseal. It was over 3 times stronger than the nearest competitor.

Strongest adhesive test results

| Product | Max pressure when adhesive bond broke (psi) |

| Adiseal | 3123 + psi |

| SupaBond | 1115 psi |

| Tec 7 | 1016 psi |

| HB42 | 942 psi |

| Loctite PL Premium | 873 psi |

| Gorilla Grab Adhesive | 862 psi |

| Bond It PU18 | 582 psi |

| Bond It Save Nails | 411 psi |

“That is actually unbelievable!”Ultimate Handyman

Testimonials

Testimonials & some comments on the: Grab adhesive tests 2017, video on YouTube

- That Adiseal is phenomenal!

- That Adiseal is some stuff though, definitely need to get some of that bought!

- I instantly went looking for Adiseal!

- Need to get my hands on some of that to try out.

- Looks like a cracking product.

- Having used the two most expensive brands on numerous occasions, I’ll be trying out the others, especially the Adiseal.

- Adiseal certainly surprised me in this test!

- Fantastic tests. It’s unbelievable that Adiseal test with the hardwood.

Benefits of Using Adiseal

Adiseal is equally great at other roofing needs like sealing lead, sealing gutters and roofing adhesive glue.

How to apply roofing felt adhesive

How to apply roofing felt adhesive

- Surface Preparation

Ensure that the surface where the adhesive will be applied is clean, dry, and free from any debris, dust, or loose materials. Repair any existing damage or cracks on the surface before proceeding.

- Application

Begin by applying a uniform layer of adhesive to the surface, covering the intended area for the roofing felt. Ensure you also coat the edges and corners to secure a strong bond.

- Roofing Felt Installation

Gently position the roofing felt onto the adhesive-coated surface, applying even pressure to ensure a secure attachment. Smooth out any wrinkles or bubbles to achieve a flat, uniform surface.

- Curing Time

Give the product ample time to cure and bond the roofing felt to the surface, following the manufacturer’s recommended curing time. Avoid any foot traffic or disturbances during this period to ensure a secure bond.

- Finishing

Once the adhesive has cured, trim excess roofing felt with a utility knife or scissors to achieve a neat finish. Inspect the installation for any areas that may require additional adhesive or touch-ups, particularly around edges, corners, and seams.

Tip: To store Adiseal once opened, leave about 1cm worth of product out of the nozzle and store the tube upright in a cool dry place. Adiseal requires moisture for it to cure. The exposed part out of the nozzle will cure creating a cap. To re-use Adiseal, pull the cured part out or cut the nozzle until the uncured part is reached.

Colours

Adiseal adhesive and sealant is available in the following colours:

- White adhesive and white sealant

- Black adhesive and black sealant

- Grey adhesive and grey sealant

- Clear adhesive and clear sealant

- Brown adhesive and brown sealant

Adiseal can also be manufactured in any RAL colour.

Please note Adiseal adhesive sealant colours provide a stronger heavy duty bond on roofing felt and other materials compared to the clear version.

Where to buy

To buy roofing felt adhesive in the UK, please contact us for you local stockist.

For other countries that do not have a Adiseal distributor, please visit www.guglue.com

Frequently asked questions about roofing felt adhesive

It can be used on various surfaces such as concrete, wood, metal, and asphalt.

Roofing felt adhesive has high-strength bonding properties that create a secure and long-lasting bond between the roofing felt and the underlying surface.

Yes, it is designed to provide a waterproof seal, preventing water from penetrating through the roof and causing leaks.

Some products are designed to be applied in damp or wet conditions, providing flexibility and convenience during installation. However, it is important to check the product specifications and follow the manufacturer’s recommendations.

Yes, it is important to clean the surface thoroughly before applying roofing felt adhesive. Removing debris, dust, and any contaminants ensures better adhesion and a stronger bond.

Using Adiseal adhesive to glue felt will provide a high-strength, flexible and waterproof bond. It is highly durable and weather resistant providing long term water resistance on roofs.