Plastic to Metal Glue

PLASTIC TO METAL GLUE: Strong, Flexible, Waterproof, Durable

To glue plastic to metal, there are different plastic to metal adhesive and glue products available. Adiseal adhesive sealant is our strongest plastic to metal adhesive where the surface area is large. For smaller surface areas, Adiglue is our best plastic to metal glue.

- What is the best plastic to metal glue?

- How to glue plastic to metal

- Where to buy plastic to metal glue or adhesive

What is the best plastic to metal glue?

There are many different products that will bond plastic to metal, but to get a good strong, long-lasting bond, use the strongest record-breaking Adiseal adhesive and sealant.

Why Adiseal is the best for bonding metal to plastic

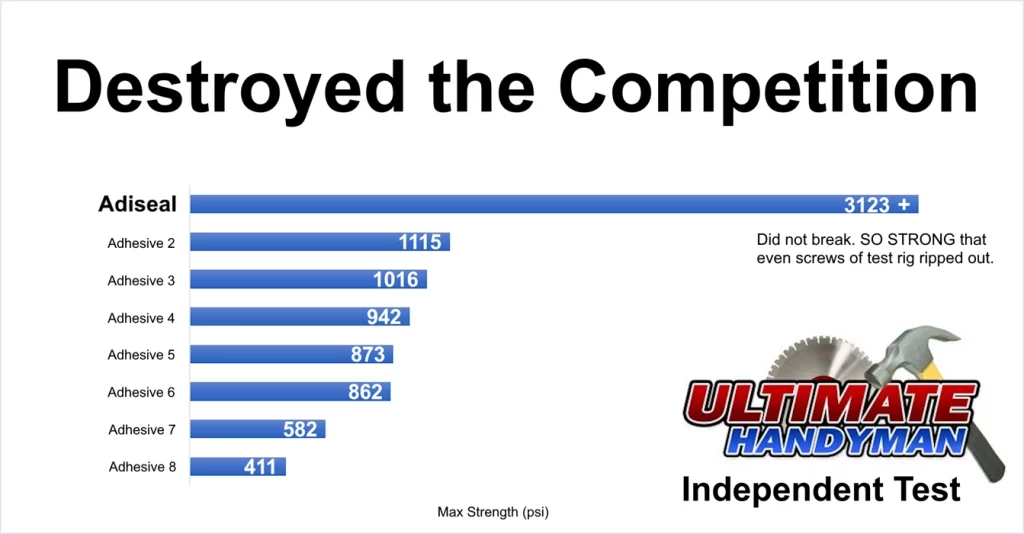

Adiseal adhesive sealant is our best product for bonding metal to plastic. In an independent adhesive strength test conducted by Ultimate Handyman, Adiseal was shown to be the strongest adhesive. It was over 3 times stronger than the closest competitor in the wood-to-metal bond strength test and also the strongest again in the metal-to-metal adhesion strength test. In fact, it was so strong that the screws holding the metal sheet down began to rip out, forcing the test on Adiseal to be stopped.

Results table of the strongest adhesive test

Strongest Adhesive Test Results

- Adiseal : 3123 + psi

- SupaBond : 1115 psi

- Tec 7 : 1016 psi

- HB42 : 942 psi

- Loctite PL Premium : 873 psi

- Gorilla Grab Adhesive : 862 psi

- Bond It PU18 : 582 psi

- Bond It Saves Nails : 411 psi

Some of the other reasons Adiseal is the best when it comes to bonding plastic to metal:

- Adiseal is the most powerful adhesive and sealant that has broken records. It’s proven to be the best product in an independent adhesive strength test by Ultimate Handyman.

- Remains permanently flexible so it will absorb any vibration and allow any item to expand and contract without weakening the adhesive.

- It is a waterproof sealant and waterproof adhesive so it is also suitable for outdoor or indoor use.

- Has very high gap filling properties.

- Has a high initial tack, which means temporary supports may not be required while the adhesive cures. Adiseal Hi-Grab has even more grip than the standard product.

- It is suitable for most plastics (not polypropylene, polyethylene or polyurethane) and most solid metals.

Problems with epoxy adhesives

There are several problems with using epoxy adhesives to bond plastic to metal. Some of the problems with epoxy adhesives are listed below.

- Although epoxy adhesives can initially bond plastic to metal, epoxy adhesives are not flexible, which means the bond will weaken over time. Changes in air temperature and humidity cause items to expand and contract by exerting additional forces on an adhesive or glue. If the adhesive or glue is not flexible, it will become weak and brittle and will eventually break. Metals are good conductors of heat, so they are likely to expand and contract easily with changes in temperature.

- Epoxy adhesives also come in 2 separate components that require mixing. To achieve the optimum properties of the epoxy adhesive, the 2 components must be in the correct ratio, therefore careful measurement is required. They should also mix well. If these 2 are not done, the optimal properties of the epoxy may not be achieved.

- Epoxy adhesives have a lower initial tack than Adiseal, which means that temporary supports will normally be required while the epoxy adhesive cures. This adds time and money with additional labor costs.

Problems with mastic adhesives

Like epoxy, mastic adhesives also present many problems when used as an adhesive for bonding metal to plastic. The main problems with mastic adhesives are listed below.

- The main problem with mastic adhesive is that the bond is weak in the first place. A mastic adhesive may be adequate for gluing lightweight items indoors, but will fail in heavier applications.

- Another problem with mastic adhesives is that they are not waterproof. This means they are not suitable for use where there will be water such as bathrooms, kitchens, or outdoors.

- Like epoxy, mastic adhesives are not flexible, which means the already weak bond will weaken over time.

- The initial tack of the mastic adhesive is also low, which means temporary supports will be required, increasing time and labor cost.

Problems with contact adhesives

Contact adhesives may be suitable for gluing lightweight foils to a surface, but not for more demanding applications. There are a number of problems with contact adhesives.

- Contact adhesives have a low initial tack, which means temporary supports will be required until the adhesive has cured.

- Contact adhesives also have low gap fill, which means that if there is a gap in certain places between the 2 surfaces of the items being joined, the contact adhesive will not stretch between the 2 surfaces. This will create a much weaker bond, as only in a few places where the surfaces are close together will the adhesive bond successfully.

Limitations

Adiseal adhesive is suitable at bonding most types of plastics but it’s not suitable for some plastics like polypropylene, polyurethane and polyethylene.

How to glue plastic to metal

How to glue plastic to metal

- Surface preparation

When attempting to bond plastic to metal, preparing both the metal and the plastic is vital to achieving a good, strong, long-lasting bond.

- Remove big gaps

Try to make sure that there are no large gaps between the surfaces where the adhesive will be applied. If there are large gaps, cut or file the surface of the plastic or metal to match where the plastic and metal meet.

- Metal preparation

To prepare the metal surface, make sure the surface is clean of dust, grease, oil, paint, rust or any other dirt. Adisolve is the ideal product for removing oil, grease, tar and other stubborn deposits.

- Plastic preparation

To prepare the plastic surface, make sure the surface is clean of dust, grease, oil, paint or any other dirt. Adisolve is the ideal product for removing oil, grease, tar and other stubborn deposits. Scratching the surface of the plastic or metal will increase the surface area for the adhesive to adhere to.

- Apply adhesive

With Adiseal, simply apply the adhesive to the plastic or metal then firmly push the metal and plastic together. When using Adiseal between 2 non-porous materials, it is advisable to spray or brush a little amount of water on 1 surface before applying the adhesive. This is because Adiseal requires moisture to cure.

- Temporary supports

As Adiseal has a high tack, temporary supports may not be required but if the item starts to slide down, fit temporary supports to hold the items in place until the adhesive has cured. Adiseal typically takes 24-48 hours to fully cure, with cure times increasing in colder temperatures.

Tip: If bonding plastic to metal where there is a possibility of water, apply the adhesive in thin vertical strips. This allows water to drain between the strips instead of pooling on the adhesive. If there is a build up of water between the plastic and the metal, in cold temperatures it will turn into ice which expands exerting additional forces on the adhesive.

Glue plastic to metal with Adiglue

It is also possible to glue plastic to metal with our Adiglue. Although Adiglue is less brittle than super glues, it is not as flexible or as strong as Adiseal adhesive sealant. Adiglue is much faster to cure than Adiseal, especially when used in conjunction with Adiglue Activator. Instead of hours, Adiglue will bond metal to plastic in a few seconds when used in conjunction with Adiglue Activator.

Bond metal to plastic with Adiseal Hi-Grab

Adiseal Hi-Grab instant grab adhesive will also bond metal to plastic. It has a higher initial tack than Adiseal adhesive sealant. However, we recommend using Adiseal adhesive sealant when gluing metal to plastic. The reason for this is that the Hi-Grab product is a very thick product. To bring together closely the 2 surfaces to be glued, requires a much higher force if the thick Hi-Grab adhesive is between the 2 materials compared to the Adiseal adhesive sealant product.

Stick other materials to plastic

Both Adiseal adhesive sealant and Adiglue will bond many other types of materials to plastic. See the glue plastic page for more details.

Bonding other materials to metal

Both Adiseal adhesive & sealant and Adiglue will bond many more other types of materials to metal. See the bond metal page for more details.

Mechanical fixing

It’s also possible to use a plastic to metal glue adhesive together with mechanical fixings like screws to further strengthen the attachment between the plastic to metal. Adiseal Ultimate metal drill bit is a great product to drill plastic and drill metal. It is also possible to drill plastic with our Adiseal Ultimate masonry multi-material drill bit but the metal drill bit provides cleaner holes in plastic.

Colours

Adiseal adhesive and sealant is available in the following colours:

- White adhesive and white sealant

- Black adhesive and black sealant

- Grey adhesive and grey sealant

- Clear adhesive and clear sealant

- Brown adhesive and brown sealant

Adiseal can also be manufactured in any RAL colour.

Please note Adiseal adhesive sealant colours are stronger than the clear version.

Where to buy plastic to metal glue or adhesive

To buy plastic to metal glue or adhesive in the UK, please contact us for details of you local stockist. For other countries that do not have a distributor, please visit www.guglue.com

Plastic to Metal Glue FAQ

Yes, you can glue plastic to metal with Adiseal and Adiglue. First clean the plastic and metal surfaces where the adhesive will be applied. Push the 2 surfaces together and hold until the adhesive dries. Temporary supports may be required until the adhesive or glue dries completely. Adiglue is recommended for use on small surface areas, while Adiseal will do so on medium and large surface areas.

The best product for bonding metal to plastic is Adiseal. It is very strong, flexible, UV resistant, waterproof and can be painted over. It has a high initial tack and was the strongest adhesive in an independent bond strength test.

Adiseal will bond metal to plastic without screws. It is extremely strong and remains flexible, which means that the adhesive bond does not become brittle. Using an adhesive to attach the plastic instead of screws provides a cleaner finish.

Adiseal Adhesive & Sealant will bond most types of plastic to all types of metal. Making sure both items are completely clean will make the strongest bond. The strength of the glue on the plastic will depend on the type of plastic being glued. There are many different types of plastics, including PVC, ABS, polycarbonate, plexiglass, methacrylate, acrylic, polyethylene, polystyrene, and many others.

Polymer, cyanoacrylate (super glue), epoxy adhesive, polyurethane adhesive, two-component acrylic adhesive, and silicone adhesive are commonly used for plastic-to-metal bonding.

Clean the surfaces thoroughly with a mild detergent to remove dirt, grease, and contaminants. Rinse and dry them properly before applying the adhesive.

Yes, roughening the surfaces using sandpaper or an abrasive material can enhance adhesion by creating a rough surface for the adhesive to grip.

Some adhesives are specifically formulated to be moisture-resistant and suitable for outdoor applications. Check the adhesive’s specifications and ensure it is suitable for your intended use.

The bonding strength varies depending on the adhesive used. Some adhesives provide high-strength bonds that can withstand mechanical stress and load-bearing applications. Consider the adhesive’s specifications and select accordingly.