Lead Sealant

LEAD SEALANT: Adiseal Waterproof Seal

Adiseal lead sealant is a high-performance waterproof product that can seal lead even in wet conditions like rain. It provides a superior weatherproof, flexible and waterproof seal on lead pointing, joints, seams, flashing and sheets. Its waterproof sealing properties makes Adiseal the ideal lead sealant for emergency repairs as well as for more long-lasting solutions like pointing between lead and brick. It is also a very strong waterproof adhesive making it also a great lead flashing glue.

- Why Adiseal is a great sealant for lead flashing

- How to prepare a surface for sealing

- How to use lead sealant

- Where to buy lead sealant

Why Adiseal is a great sealant for lead flashing

When it comes to choosing the ultimate sealant for lead flashing, lead sheet, pointing, joints or seams, Adiseal stands out as the top choice. Here’s why Adiseal excels as a lead sealer and adhesive:

- Strongest Adhesive: Independently tested and proven to be the strongest adhesive, Adiseal ensures secure and reliable bonding between lead materials and other surfaces.

- Instant Sealing: Adiseal provides immediate and effective water penetration prevention, safeguarding against leaks and potential water damage.

- Permanent Seal: It offers a long-lasting seal that withstands the test of time, ensuring lasting protection for lead flashing.

- Flexibility: Adiseal remains permanently flexible, accommodating natural movements and thermal expansion/contraction of lead materials, preventing cracking or detachment. This makes it an ideal sealant for lead pointing between lead and brick or other building materials.

- UV Resistance: UV-resistant, Adiseal endures prolonged exposure to sunlight without degradation, ensuring durability and performance in outdoor applications.

- Cold Application: It can be applied in cold temperatures, making it suitable for various weather conditions and seasons.

- Mould Resistance: Adiseal’s unique formula resists mould growth, preventing unsightly and potentially harmful mould development on sealed surfaces.

- Solvent Free: Being solvent-free minimizes health risks and enhances safety for use in enclosed or poorly ventilated spaces.

- Waterproof: Adiseal serves as an efficient waterproof adhesive and sealant, creating an impermeable barrier and weatherproof seal that guards against water intrusion and potential water-related damages.

- Versatility: It performs reliably in dry and wet conditions, making it suitable for various applications, including underwater use, offering exceptional versatility and convenience. It is also able to seal metal of many different types.

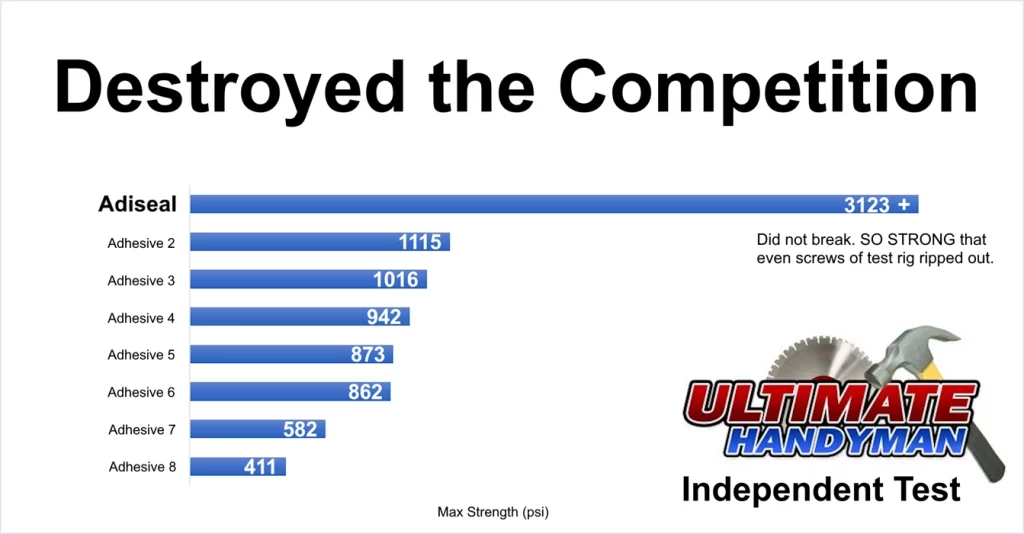

Independent test

As well as Adiseal being used for lead sealing, it is also a great flashing glue adhesive. It will glue lead flashing to many different building materials including, brick, felt, concrete, stone, masonry and slate to name a few.

In an independent test by Ultimate Handyman, Adiseal was found to be the strongest product. In the test, no other product came even close to Adiseal.

Adiseal’s remarkable strength exceeded expectations, even causing the screws securing the test rig to begin tearing out, ultimately halting the Adiseal test. For a firsthand look at this impressive demonstration of Adiseal’s power, watch the test video on YouTube and be astonished by its exceptional strength and performance in this adhesive test.

As well as Adiseal lead sheet sealant being able to seal, it will also provide the strongest bond whether the lead flashing is being fitted to a rendered wall, a pitched roof or any other surface.

Instant Sealing and Verification with Adiseal

Adiseal’s remarkable feature is its instant sealing capability, offering immediate verification of successful lead sealing.

Instant Seal: Adiseal swiftly seals when used for lead roof repair, creating a strong, dependable barrier against water infiltration as soon as it’s applied.

Verification Process: After the repair, you can promptly check the effectiveness of the lead sealant. Pour water onto the repaired area with Adiseal and observe its behavior to determine the success of the sealing.

Water Test: Pour water onto the lead flashing sealant, watching for any signs of leakage or seepage. A successful seal will keep the water contained within the repaired area, preventing water damage as it remains on the surface without penetrating through.

Using Adiseal’s instant sealing capabilities and conducting a water test enables a quick assessment of your lead roof repair’s success. This provides immediate feedback and confidence that the sealant has effectively protected your roof from potential water intrusion and related issues.

Adiseal: Delivering a Lasting and Reliable Seal

Adiseal offers a lasting solution for repairing lead flashing:

- Permanent Seal: Adiseal forms a durable bond, ensuring a long-lasting seal that provides peace of mind.

- Exceptional Durability: Adiseal’s strong formulation and adhesive properties make it highly durable, even in harsh conditions like UV exposure, temperature variations, and moisture.

- Reliable for Years: When used correctly, Adiseal ensures a secure and reliable repair that withstands the elements over time.

- Trusted Choice: With a proven track record and strong customer satisfaction, Adiseal is the trusted choice for professionals and DIY enthusiasts seeking a permanent fix for lead flashing.

Unwavering Flexibility for Lasting Performance

Adiseal’s standout feature is its permanent flexibility, setting it apart for these reasons:

- Resistance to Brittleness: Unlike other products that can become brittle and crack with temperature fluctuations, Adiseal maintains its flexibility. It adapts to temperature changes, preventing compromise in its sealing capabilities.

- Reliable Performance: Adiseal’s permanent flexibility ensures it won’t develop cracks or fractures that lead to water leakage. It withstands temperature variations, preserving the seal’s integrity and long-lasting protection against water infiltration.

- Adapts to Expansion and Contraction: As materials expand and contract due to environmental factors, Adiseal remains flexible without losing its sealing properties. This resilience effectively maintains a secure bond and prevents potential damage or water penetration.

- Extended Lifespan: When used for sealing lead sheet flashing, Adiseal offers a significantly longer lifespan compared to other sealants. Its permanent flexibility keeps the seal intact and effective over an extended period, reducing the need for frequent repairs or replacements.

UV Resistant: Shielding Your Seal from Sun’s Harmful Rays

UV resistance is crucial for sealant longevity, especially for sun-exposed roofs:

- Protection from Solar Impact: Roofs endure direct sunlight and intense UV radiation. Without UV resistance, sealants deteriorate rapidly, leading to cracks, discoloration, and integrity loss.

- Enhanced Durability: UV-resistant sealants like Adiseal withstand long-term sun exposure, remaining stable and preventing premature degradation for lasting performance.

- Extended Lifespan: UV-resistant sealants significantly extend seal lifespans, maintaining protection and structural integrity despite continuous UV exposure. This ensures continued effectiveness against water infiltration.

- Reliable Performance: UV resistance signifies a sealant’s quality and its ability to endure harsh outdoor conditions. UV-resistant sealants, such as Adiseal, excel in outdoor applications, withstanding intense sunlight without compromising sealing capabilities.

Solvent-Free: A Strong and Safe Choice for Lead Sealing

Adiseal lead sealer’s solvent-free formulation sets it apart for these reasons:

- Non-Shrinking Performance: Unlike solvent-based sealants that can shrink upon curing, Adiseal maintains its original size, ensuring a secure and long-lasting bond.

- Enhanced Bonding: Adiseal’s solvent-free composition enhances bonding strength compared to cheaper, solvent-heavy alternatives. It creates a reliable and durable seal that withstands time and environmental stresses.

- Compatibility with Sensitive Materials: Solvent-based sealants can harm sensitive materials like polystyrene insulation. Adiseal’s solvent-free formula ensures compatibility with a wide range of materials, including sensitive ones.

- Low VOC Certification: Adiseal is EC1 Plus certified, signifying its low VOC (Volatile Organic Compounds) content. This certification reflects Adiseal’s commitment to safety and environmental responsibility, contributing to healthier indoor air quality and a better environment.

Versatile Performance: Adiseal Thrives in Dry, Wet, and Underwater Conditions

Adiseal excels in diverse environmental conditions, making it ideal for emergency repairs and sealing lead pointing, even in challenging weather:

- Rain or Shine: Adiseal confidently handles emergency repairs during rain, ensuring a reliable, waterproof seal to prevent further water infiltration.

- Wet Environments: Adiseal’s strong adhesion and sealing capabilities work on damp surfaces, even in wet conditions, surpassing traditional sealants’ limitations.

- Underwater Applications: Unlike many sealants, Adiseal bonds and seals underwater effectively.

Versatile Applications: Adiseal’s Multi-Purpose Capabilities

Adiseal excels in various projects beyond its lead sheet sealing and adhesive capabilities:

- Leaking Gutter Repairs: Adiseal effectively repairs leaking gutters by forming strong bonds and waterproof seals, preventing water damage.

- Felt Roof Restoration: Adiseal is a dependable choice for felt roof repairs, sealing gaps or tears and ensuring long-lasting protection against water infiltration.

Adiseal’s versatility extends to common maintenance and repair tasks, making it a reliable solution for multiple applications.

How to prepare a surface for sealing

Surface Preparation

- Cleaning the Lead Surface is a critical step before applying a lead sheet flashing sealant. Thoroughly clean the lead surface to remove dirt, dust, or debris using a soft brush or cloth. Ensure the surface is free from any substances that may impede proper adhesion.

- Inspect the lead surface for loose particles, such as flaking paint or rust. Gently remove these particles using a wire brush or sandpaper to achieve a clean and smooth surface. Additionally, address any oxidation on the lead by gently cleaning or treating the affected area.

How to use lead sealant

How to use lead sealant

- Prepare the surface

Ensure the surface is clean, dry, and free from dust, grease, or debris. Use a brush or cloth to remove loose particles and contaminants.

- Cut the nozzle

Cut the sealant tube nozzle at an angle to match the desired bead size. Attach the nozzle to the tube and load it into a sealant gun.

- Apply the sealant

Squeeze the trigger to apply a continuous bead of sealant along the joint or surface. Move the nozzle steadily for even application.

- Tool the sealant

Smooth the sealant bead with a tool to ensures proper adhesion and a clean finish.

- Allow to cure

Follow the manufacturer’s instructions for curing time, typically 24-48 hours. Avoid disturbing the area during the curing process.

- Clean up

Wipe away any excess sealant immediately with a cloth or scraper. For dried sealant, use a suitable remover or mechanical means.

Where to buy lead sealant

To buy lead sealant in the UK, please contact us for details of your local stockist. For other countries that do not have a distributor, please visit www.guglue.com

Frequently asked questions about lead sealant

Lead sealant is a type of adhesive specifically designed for sealing and bonding lead materials, such as lead flashing, to various surfaces.

The purpose of using lead sealant is to create a watertight and durable seal between lead materials and other surfaces, preventing water infiltration and ensuring long-lasting protection.

Factors to consider when choosing a lead sealant include compatibility with lead materials, application requirements, environmental considerations, curing time, and desired flexibility.

Yes, lead sealant can be used on surfaces other than lead, such as concrete, wood, metal, and plastic, as long as it is compatible with the specific surface material.

Some lead sealants are formulated to be UV resistant, which helps prevent degradation and maintain the sealant’s performance and appearance over time.

The surface should be clean, dry, and free from dirt, dust, grease, and loose particles. It may also be necessary to use a primer or surface conditioner for optimal adhesion.

Certain lead sealants are formulated to work in wet or underwater conditions, allowing for repairs and sealing in challenging environments.

Many lead sealants are designed to remain flexible even after curing. This flexibility helps accommodate thermal expansion and contraction, ensuring the seal remains intact over time.