Panel Adhesive

Wall Panel Adhesive: Strong Waterproof Glue Bond on Paneling

Adiseal wall panel adhesive is a high-performance product that provides a high-strength bond on many different types of panels, paneling and boards. As well as the high adhesive bond strength, Adiseal is also flexible, waterproof and durable. It can glue panels to walls in both interior and exterior applications.

- Why Adiseal is a great adhesive for panels

- What materials will Adiseal stick to

- How to bond panels to wall

- How to stick panels with a panel adhesive

There are many types of panels and boards that Adiseal can glue, including:

- PVC panels

- Shower panels

- Wall panels

- Bathroom panels

- Wood paneling

- Many more paneling and boards.

Why Adiseal is a great adhesive for panels

Adiseal is the perfect adhesive for paneling due to its record-breaking strength, flexibility, waterproof properties, and other key features:

- Unmatched strength: Adiseal has undergone independent testing and proven to be the strongest adhesive and sealant available.

- Flexible and durable: It maintains flexibility to accommodate vibrations and movements without weakening or becoming brittle.

- Waterproof performance: Adiseal is fully waterproof, making it suitable for both indoor and outdoor applications, including underwater use.

- No priming required: Save time and money as Adiseal does not require priming, as long as the surface is clean.

- Non-staining formula: Adiseal won’t stain or bleed into marble, stone, or other porous materials, preserving their appearance.

- Excellent gap-filling properties: Even on uneven surfaces, Adiseal provides high gap fill capabilities for a strong bond.

- Strong initial grab: Adiseal offers a high initial grab, reducing the need for temporary supports during the curing process. Adiseal Hi-Grab is available for more demanding applications where even higher initial grab is required.

Performance

The record breaking strongest Adiseal adhesive and sealant will bond and seal on many different materials.

In our demonstration as shown in the above image, we bonded a concrete block and PVC together using Adiseal adhesive and sealant. Despite the concrete being porous, we achieved a strong bond without the need for surface sealing. Adiseal’s exceptional performance properties allow it to adhere to porous surfaces without bleeding or staining concerns.

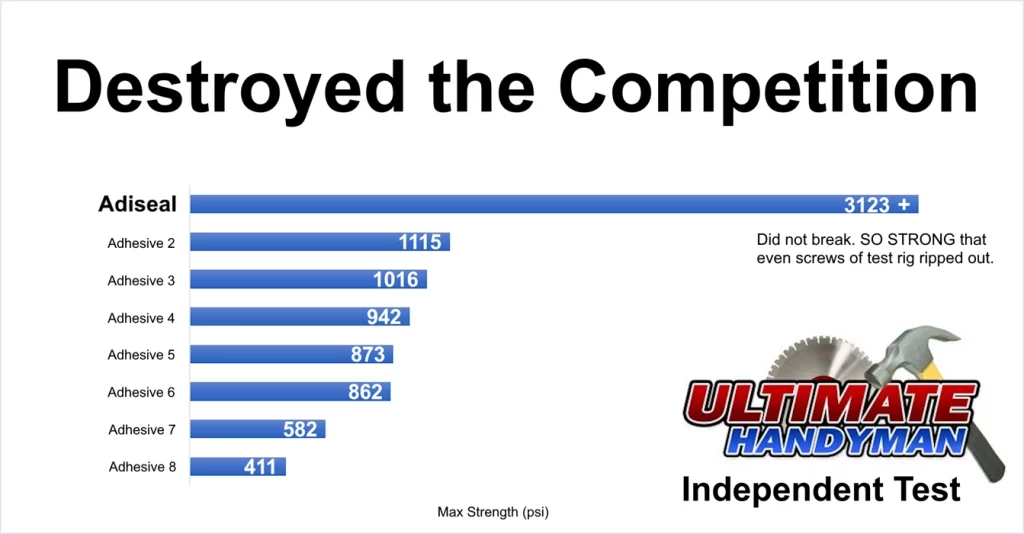

Strongest adhesive in independent test

In an independent adhesive strength test, Adiseal surpassed its closest competitor by over three times in adhesive strength. The test had to be stopped at 3123 psi as the screws securing the test rig started to tear out. Adiseal would have achieved even greater strength if the screws had not given way. Rest assured, with Adiseal, you can trust in its exceptional strength and reliability for all your bonding needs.

What materials will Adiseal stick to

Adiseal will successfully bond the following materials

Benefits of Adiseal

Adiseal Adhesive Sealant vs Adiseal Hi-Grab

For an adhesive with higher strong initial grab, consider Adiseal Hi-Grab. It provides an even stronger initial grab than the standard Adiseal adhesive, making it perfect for heavy-duty applications or scenarios where temporary supports cannot be used during the curing process. Both Adiseal adhesive sealant and Adiseal Hi-Grab offer comparable final bond strength.

How to bond panels to wall

Adiseal bonds panels to walls, ceilings and other surfaces effectively, creating a strong and durable bond suitable for both indoor and outdoor applications. Before applying the adhesive, it’s crucial to ensure clean surfaces free from dust, grease, paint, or any other debris. Using a fine brush, such as a painting brush, can help remove fine dust and prepare the surfaces for bonding.

Before applying the adhesive, ensure the concrete surface is dust-free. We recommend using a fine brush like a painting brush to remove fine dust from masonry.

Once the surfaces are clean, apply the adhesive to either the panel or other surface and firmly press them together. When bonding in a potentially wet area, apply Adiseal in thin vertical strips to allow water to run down between the strips and prevent water buildup that can weaken the bond. In cold temperatures, this water may freeze and expand, compromising the bond.

Temporary supports may not be necessary, but if the panel starts to slide, consider using temporary supports until the adhesive cures, which can take up to 48 hours.

To glue wood paneling, as wood tends to absorb moisture and expand or contract, it’s crucial to use a flexible adhesive for wood paneling. This flexibility allows for expansion and contraction without making the adhesive bond brittle.

For added safety when bonding heavy wood panel items in vertical or overhead applications, it is recommended to use mechanical fixings along with an adhesive.

How to stick panels with a panel adhesive

How to stick panels with a panel adhesive

- Prepare the surfaces

Ensure that both the panel surface and the surface you want to bond it to are clean, dry, and free from dust, dirt, grease, or any other contaminants. Clean the surfaces using a mild detergent and water if needed.

- Apply the adhesive

Apply a thin, even layer of adhesive to either the panel surface or the surface you want to bond it to. You can use a brush or a suitable applicator to spread the adhesive evenly.

- Press and hold

Carefully align the panel piece with the target surface and firmly press it into place. Apply even pressure across the entire surface to ensure a strong bond. Hold the panel in place for a few moments to allow the adhesive to start bonding.

- Cure time

Follow the instructions provided by the adhesive manufacturer regarding the recommended curing time. Adiseal typically takes around 24-48 hours to fully cure, but the exact time may vary depending on factors such as temperature and humidity.

- Avoid movement

Avoid disturbing or putting stress on the bonded panel during the curing process. This will help ensure a strong and durable bond.

Tip: When bonding items in a potentially wet environment, apply the adhesive in thin vertical strips. This enables water to drain between the strips, preventing it from pooling on the adhesive. Accumulated water can freeze in cold temperatures, exerting extra forces on the adhesive.

Colours

Adiseal adhesive and sealant is available in the following colours:

- White adhesive and white sealant

- Black adhesive and black sealant

- Grey adhesive and grey sealant

- Clear adhesive and clear sealant

- Brown adhesive and brown sealant

Adiseal can also be manufactured in any RAL colour.

Please note the Adiseal adhesive for panels colours are stronger and have a higher initial grab than the clear version.

Where to buy panel adhesive?

In the UK to buy adhesive for paneling, please contact us for details of your local stockist. For other countries visit www.guglue.com

Frequently asked questions about panel adhesive

Panel adhesive is a type of adhesive used for bonding various panels, such as wood, plastic, metal, or composite panels, together. The panels can be bonded on walls, floor or ceiling.

Adiseal provides a high strength, durable, flexible, mould resistant, UV resistant & waterproof bond on panels. It bonds panels made from different materials including PVC, wood, metal & more.

Panel adhesive is commonly used in woodworking, carpentry, construction, and automotive industries for tasks like bonding panels to substrates, laminating panels, or repairing panels.

Panel adhesive can be used to bond a wide range of materials, including wood, MDF (medium-density fiberboard), plywood, metal, plastic, and composites.

Some panel adhesives are formulated for interior use only, while others are suitable for both interior and exterior applications. Be sure to check the product specifications for suitability.

Some panel adhesives can be painted over, while others may not accept paint well. Check the product specifications for paintability.

Adiseal is a high performance uPVC wall panel adhesive. It will provide a high-strength, durable, flexible, waterproof, UV resistant & mould resistant adhesive bond.