Slate Adhesive

Slate Adhesive: Stick Roof Slate & Other Materials

Adiseal slate adhesive is a high-performance bonding solution crafted for slate, limestone, granite, marble, masonry, and various stones. Engineered for exceptional strength, water resistance, durability, and flexibility, Adiseal ensures a reliable bond. Its weatherproof characteristics make it suitable for both interior and exterior applications, excelling in slate bonding and sealing tasks. Adiseal proves versatile as a slate adhesive, showcasing superior bonding capabilities.

This adhesive seamlessly bonds granite to a range of materials, including wood, metal, plastic, concrete, stone, and brick. In independent adhesive strength tests, Adiseal has demonstrated its supremacy, surpassing other adhesives in securely adhering slate and various materials.

Why Adiseal is a great adhesive for slate

Adiseal is recognized as high-performance adhesive for slate, limestone, marble, granite, masonry, and various stone materials, distinguished by its remarkable strength, flexibility, waterproofing capabilities, and a range of other essential features.

- Adiseal’s strength has been affirmed through independent testing, solidifying its position as the strongest adhesive and sealant available.

- Maintaining flexibility, Adiseal withstands vibrations and movements without compromising strength or becoming brittle.

- With complete waterproofing, Adiseal proves versatile for indoor and outdoor applications, including underwater use.

- No priming required: Adiseal eliminates the need for priming, saving time and money, as long as the surface is clean.

- Adiseal’s non-staining formula ensures it won’t bleed into porous materials like marble, granite, or stone, preserving their appearance without any risk of staining.

- With outstanding gap-filling properties, Adiseal guarantees a strong bond even on uneven surfaces.

- Boasting a strong initial grab, Adiseal reduces the need for temporary supports during the curing process. For more demanding applications requiring an even higher initial grab, Adiseal Hi-Grab is available.

Performance

Adiseal, the exceptionally powerful adhesive and sealant, can efficiently bond and seal a wide range of materials.

In a demonstration, we effectively adhered marble to a porous concrete block using Adiseal adhesive and sealant. This robust bonding took place without the need to seal the surfaces, highlighting Adiseal’s impressive capability to bond porous materials without concerns of bleeding or staining.

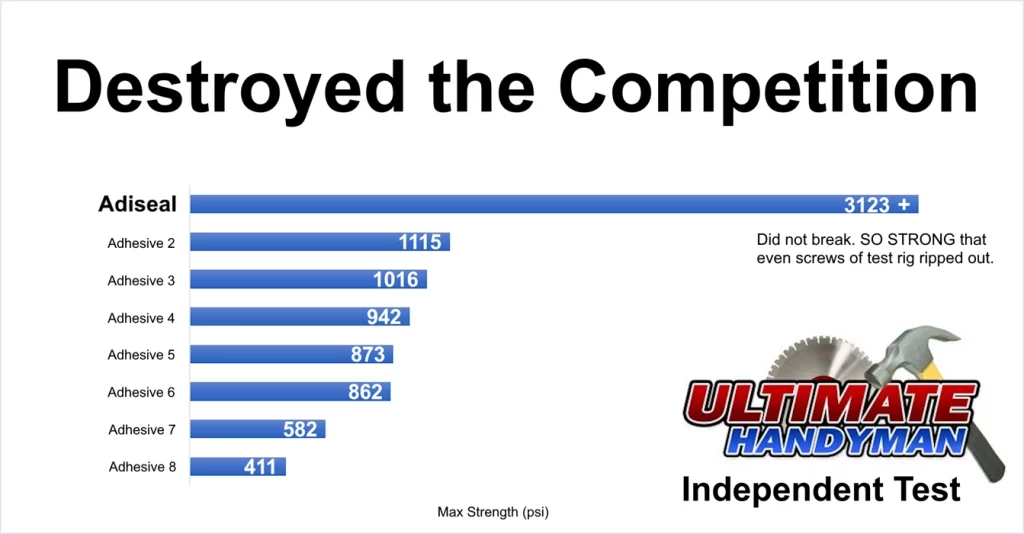

Strongest adhesive in independent test

In an independent adhesive strength test, Adiseal exhibited more than three times the strength of its nearest competitor, reaching an impressive 3123 psi. The test had to be stopped due to the screws securing the test rig starting to fail. Adiseal could have achieved even greater strength if the screws had not given way.

Adiseal Adhesive Sealant vs Adiseal Hi-Grab

For a superior initial grip strength in an adhesive, consider Adiseal Hi-Grab. It provides an even stronger initial hold than the standard Adiseal adhesive, making it perfect for heavy-duty applications or scenarios where temporary supports cannot be used during the curing process. Both Adiseal adhesive sealant and Adiseal Hi-Grab offer comparable final bond strength.

How to stick slate with adhesive

How to stick slate with adhesive

- Surface Preparation

Ensure that the surfaces you plan to bond are clean, dry, and free from dust, grease, or other contaminants. Clean the slate and the substrate thoroughly.

- Application

Apply the adhesive to 1 surface. Covering as much area as possible will provide a better bond. Don’t apply too much adhesive that it squeezes out of the sides when the 2 materials are pushed together.

- Pressing Surfaces Together

Press the slate firmly onto the prepared surface with the adhesive. Apply even pressure to ensure good contact between the adhesive and the slate.

- Temporary support (if required)

Depending on the application and the weight of the slate, consider using clamps or other means to hold the surfaces together while the adhesive cures.

- Curing Time

Allow the adhesive to cure for the recommended duration specified by the product instructions. Typically, it can take Adiseal 48 hours for a full cure.

- Avoid Disturbance

Avoid subjecting the bonded slate to stress or load until the adhesive has fully cured. This is crucial to ensure a strong and durable bond.

For reliable bonding of substantial materials such as slate, limestone, granite, marble, stone, or masonry items, it is recommended to utilize both adhesive and mechanical fixings, particularly in vertical or overhead applications. This dual method enhances stability and provides additional support, reducing the likelihood of the bonded items detaching or falling.

Suggestion: When bonding items in damp conditions, consider applying the adhesive in narrow, vertical strips. This allows water to drain between the strips, preventing pooling. In colder temperatures, accumulated water might freeze, potentially impacting the adhesive’s effectiveness.

Glue for slate

Adiglue can be used as an adhesive for slate, limestone, granite, marble or other stones but it lacks the strength and flexibility of Adiseal construction adhesive & sealant or Adiseal Hi-Grab adhesive.

To demonstrate we used Adiglue successfully bond a metal handle to a sturdy concrete slab. Prior to application, Adiglue Activator was applied to the concrete surface to prevent absorption. Nevertheless, when using Adiseal adhesive & sealant or Adiseal Hi-Grab to affix metal handles to concrete, marble, or granite, there is no need for concrete sealing.

Colours

Adiseal adhesive and sealant is available in the following colours:

- White adhesive and white sealant

- Black adhesive and black sealant

- Grey adhesive and grey sealant

- Clear adhesive and clear sealant

- Brown adhesive and brown sealant

Adiseal can also be manufactured in any RAL colour.

Where to buy slate adhesive?

In the UK to buy slate adhesive or slate glue, please contact us for details of your local stockist. For other countries visit www.guglue.com

Frequently asked questions about slate adhesive or glue

To bond slate, Adiseal adhesive has been shown to provide a strong, flexible, waterproof and durable bond on granite. It can be applied to try or wet surfaces.

Yes, products like Adiseal slate adhesives are formulated to withstand outdoor conditions, providing weather-resistant and waterproof bonds.

Adiseal slate adhesive is formulated for bonding slate and many other materials.

Adiseal slate adhesive is designed to resist water and withstand weather conditions, ensuring longevity in outdoor applications.