Cobalt Drill Bits

What are the Best Cobalt Drill Bits

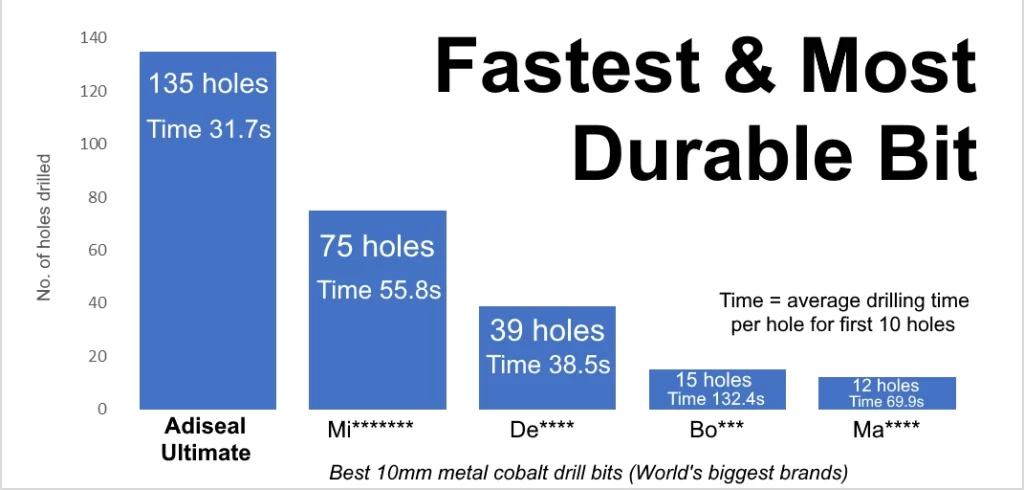

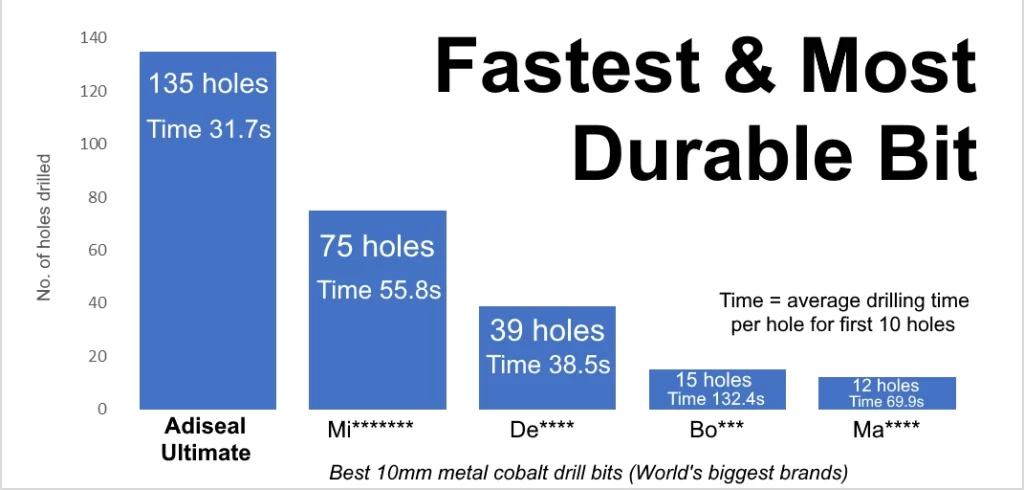

To find out what are the best cobalt drill bits, we carried out drilling speed and bit durability tests on the best cobalt metal drill bits from the worlds top brands. In our tests, Adiseal Ultimate cobalt drill bits for metal have been shown as the superior choice when it comes to metal drill bits. It showed exceptional strength and speed, outperforming all other metal drill bits available.

In our tests, it drilled faster and drilled more holes than any competing metal drill bits, surpassing even the top brands including DeWalt, Bosch, Milwaukee, and Makita. The impressive Adiseal Ultimate cobalt metal drill bit managed to drill 9 times the number of holes than what the best cobalt metal drill bit from Bosch managed and over 3 times the number of holes than the best cobalt metal drill bit from DeWalt. See the table below for the results.

- Best cobalt metal drill bit durability test results

- Cobalt metal drill bit test procedure

- How to use a cobalt metal drill bit

- What materials can it drill into

Best cobalt metal drill bit durability test results

| 10mm metal cobalt drill bit | Total number of holes drilled (in 6mm stainless steel) |

| Adiseal Ultimate cobalt | 135 holes |

| Milwaukee cobalt red | 75 holes |

| DeWalt Extreme cobalt | 39 holes |

| Bosch cobalt | 15 holes |

| Makita cobalt | 12 holes |

Impressively, Adiseal Ultimate drilled more holes than the best cobalt bits from the top 3 worlds biggest brands combined. (Milwaukee cobalt red) 75 + (DeWalt Extreme cobalt) 39 + (Bosch cobalt) 15 = 129 holes vs Adiseal Ultimate 135 holes .

Best metal drill bit speed test results

In addition to drilling the highest number of holes among metal drill bits, the Adiseal Ultimate bit also boasts the fastest drilling speed, showing its the best cobalt drill bit. In the same test mentioned earlier, we measured the time taken to drill each hole, recording the average time for the first 10 holes as shown in the table below.

| 10mm metal cobalt drill bit | Average time to drill each hole (in 6mm stainless steel) for first 10 holes |

| Adiseal Ultimate cobalt | 31.7 seconds |

| DeWalt Extreme cobalt | 38.5 seconds |

| Milwaukee cobalt | 55.8 seconds |

| Makita cobalt | 69.9 seconds |

| Bosch cobalt | 132.4 seconds |

Adiseal Ultimate was over 4 times faster the best cobalt bit from Bosch.

By drilling faster and more holes than any other bit, Adiseal Ultimate cobalt drill bit saves money, time, tools and energy.

Please note, these are our test results from internal testing. We recorded a video of each hole being drilled. These videos are available on request for your test accuracy verification purposes.

Cobalt metal drill bit test procedure

We performed tests using a Scheppach DP60 drill press to drill 10mm holes in 6mm thick stainless steel (SUS304) with the various cobalt drill bits. The drill press was set to consistently maintain a speed of 400 rpm for all the bits tested, including 10mm metal cobalt drill bits from renowned brands like Milwaukee Cobalt Red, DeWalt Extreme, Bosch Cobalt, and Makita.

To ensure uniformity, a 5kg weight was suspended on the drill press arm during each hole’s drilling to maintain consistent force and RPM. Notably, we conducted durability tests without lubricants, coolants, or cutting oils, though these substances can aid in reducing the bit’s temperature and extending its lifespan. The drilling processes were recorded and timed using video timestamps. Following these tests, the Adiseal Ultimate drill bit emerged as the top performer, excelling in both the number of holes drilled and the time taken for each hole.

It’s essential to highlight that non-cobalt drill bits, such as HSS bits (high-speed steel), including Milwaukee Thunderweb and Bosch PointTeq, were tested but were excluded from the chart to ensure fairness. Notably, Bosch PointTeq couldn’t drill any holes into the 6mm thick stainless steel SUS304 during the testing.

Kindly note, these results stem from our internal testing. We have video recordings of each hole drilled, available upon request for your verification to ensure test accuracy.

Savings

Saves money

In the long run, inexpensive drill bits might become more costly if they wear out faster and drill fewer holes compared to durable ones. Determine the cost per hole by dividing the bit’s price by the total holes drilled. Cheaper bits could potentially have a higher cost per hole than more resilient options. Notably, in our test, Bosch PointTeQ’s non-cobalt bit couldn’t drill any holes, whereas the Adiseal Ultimate metal drill bit successfully drilled 135 holes.

Example of cost per hole

To compare costs, let’s consider drilling 10 holes in 6mm stainless steel with the Adiseal Ultimate and Bosch cobalt drill bits.

Adiseal Ultimate 10mm metal drill bit price: £10.14

Cost per hole (£10.14 / 135 holes): £0.076666

Cost to drill 10 holes: £0.77

Bosch cobalt metal drill bit price: £8.31

Cost per hole (£8.31 / 15 holes): £0.554

Cost to drill 10 holes: £5.54

Based on cost per hole, Adiseal is more cost-effective. Further savings can be observed as detailed below.

Saves time

A drill bit that drills faster not only decreases the cost per hole but also lowers labor expenses. The reduced drilling time per hole leads to additional cost savings overall.

Example of saving money on labour cost

To showcase potential labour cost savings, let’s examine the time and effort needed to drill 10 holes in 6mm stainless steel using the Adiseal Ultimate and Bosch cobalt bits.

Assuming a construction contractor pays £20 per hour for a tradesperson’s work, it amounts to £0.00555 per second.

Adiseal Ultimate: 317 seconds to drill 10 holes.

Labour cost: £1.76

Bosch cobalt: 1324 seconds to drill 10 holes.

Labour cost: £7.36

Adding these labour costs to the drilling costs above, total cost to drill 10 holes is:

Adiseal Ultimate: £2.53

Bosch cobalt: £12.90

In reality, further savings arise from extended tool lifespan, decreased energy consumption per hole, and fewer trips required to purchase replacement bits.

Saves tools

Quicker drilling extends the tool’s lifespan by minimizing usage. Slower drilling bits prolong runtime, potentially leading to faster wear. Tools with extended lifespans can result in additional cost savings.

Saves energy

Quicker drilling decreases tool runtime, conserving energy and generating additional savings beyond those mentioned. The reduced energy required for drilling each hole also positions the Adiseal Ultimate as the most environmentally friendly metal drill bit.

Other benefits

Adiseal Ultimate cobalt drill bits, with their sharp cutting edge, eliminate the need for pilot holes, preventing sliding and wandering. Additionally, they create larger pieces, minimizing the necessity to clear multiple small chips post-drilling, thus delivering cleaner cut holes compared to alternative bits.

How to use a cobalt metal drill bit

How to drill with a cobalt metal drill bit

- Safety First

Put on safety goggles to protect your eyes from debris.

- Setup

Secure the metal piece firmly in place using clamps or a vise to prevent movement during drilling.

- Marking

Use a center punch or awl to create a starting point on the metal surface. This helps guide the drill bit and prevents it from slipping.

- Drilling Angle

Hold the drill perpendicular to the metal surface to ensure a straight and precise hole.

- Drilling Speed

Start drilling at a slow speed to prevent overheating and allow the bit to grip the metal surface. Once the bit has established a groove, gradually increase the drill speed.

- Lubrication

Consider using a lubricant or cutting oil to reduce friction and heat buildup during drilling. This helps extend the lifespan of the drill bit.

- Steady Pressure

Apply constant and steady pressure while drilling to maintain control and prevent the bit from wandering.

- Cooling Periods

Periodically stop drilling to let the bit and metal cool down if they become too hot. This prevents damage to both the bit and the metal surface.

- Clean-up

Once drilling is complete, remove the drill bit slowly while the drill is still running to clear any remaining metal debris. Clean the drilled hole and the metal surface.

Be cautious when handling the drilled material or the drill bit afterward, as they might still be very hot. Hot metal can cause burns, so either let them cool before touching with bare hands or use suitable heat-resistant gloves.

Exercise caution when handling the removed chips as they can be extremely sharp and easily cause cuts. If you need to handle them, it’s advisable to wear gloves for protection.

What materials can it drill into

Adiseal Ultimate heavy duty cobalt metal drill bit is also suitable at drilling many other materials including:

- Stainless steel

- Hardened steel

- Metal

- Aluminum

- Bronze

- Brass

- Copper

- Cast iron

- Plain carbon steel

- Wood

- Plastic

- Fiberglass

- Plus many other materials

What sizes are Adiseal Ultimate cobalt metal drill bits available in?

Adiseal Ultimate cobalt metal drill it is currently available in the following sizes:

- 2.5mm x 62mm

- 3mm x 72mm

- 3.5mm x 74mm

- 4mm x 84mm

- 4.5mm x 87mm

- 5mm x 94mm

- 5.5mm x 97mm

- 6mm x 104mm

- 6.5mm x 107mm

- 7mm x 107mm

- 8mm x 116mm

- 9mm x 127mm

- 10mm x 133mm

- 11mm x 140mm

- 12mm x 149mm

- 13mm x 152mm

Where to buy cobalt drill bits for metal

In the UK to buy cobalt drill bit for metal, please contact us for details of your local stockist. For other countries, please visit www.guglue.com

Adiseal Ultimate Masonry & Multi Material Drill Bit

In their attempt to make available the best drill bits, also in the Adiseal Ultimate range is the fastest no hammer masonry drill bit & multi material drill bit. It can drill faster than any other drill bit when drilling without hammer function on the drill. This gives it numerous advantages over hammer drills. It will drill into brick, drill concrete, wood and many other building materials. This carbide bit has been shown to be the best masonry drill bit with a hex shank.

Frequently asked questions about metal drill bits

Cobalt drill bits are used for drilling tough materials such as stainless steel, cast iron, and high-strength alloys. They’re designed with a blend of cobalt and high-speed steel for durability and heat resistance, ideal for high-temperature drilling in these materials. Their enhanced strength makes them effective where regular bits might struggle or wear out.

Cobalt drill bits are some of the strongest options for tough materials like stainless steel. They’re highly durable and heat-resistant due to their blend of cobalt and high-speed steel. While they’re quite strong, there might be specialized drill bits with unique compositions designed for specific purposes that are also exceptionally robust.

The cobalt percentage in drill bits indicates the cobalt content in the high-speed steel (HSS) used.

5% Cobalt Bits: These contain around 5% cobalt, offering decent durability for general drilling in materials like steel, aluminum, and wood. They might not handle extreme heat as well as higher cobalt content bits.

8% Cobalt Bits: With roughly 8% cobalt, these bits are more heat-resistant and durable. They’re suitable for harder materials like stainless steel and cast iron, handling higher drilling temperatures effectively.

Higher cobalt content generally improves heat resistance and durability, especially for challenging drilling tasks.

While cobalt drill bits can be used on wood, they’re primarily designed for tough materials like stainless steel and cast iron. For woodworking, standard high-speed steel (HSS) or brad point drill bits are more suitable, offering efficient and precise drilling in wood. Cobalt bits might work on wood, but they might not provide the same precision or efficiency as bits designed specifically for woodworking tasks.

Yes, cobalt drill bits are specifically designed to drill through tough materials like stainless steel. Their construction, which often includes a mix of cobalt and high-speed steel (HSS), provides enhanced durability and heat resistance, making them well-suited for drilling into stainless steel and other hard alloys. These bits are more effective in handling the high temperatures generated during drilling into tough materials, making them suitable for such applications.