Hex Shank Masonry Drill Bit

Hex Shank Drill Bits: Masonry & Multi-Material

Adiseal Ultimate has been shown to be the best hex shank drill bit in our test drilling into masonry. It drills faster and drills more holes than any other masonry drill bit when drilling without hammer function on the drill. Drilling hard materials like masonry, brick or concrete without hammer has many advantages over hammer drilling.

- What are the advantages of no-hammer drilling with a hex shank

- Adiseal Ultimate Hex Shank (No Hammer) vs SDS Hammer Drill Speed Test

- How to use a he shank drill bit

- What materials can it drill into

What are the advantages of no-hammer drilling with a hex shank

Advantages of drilling masonry without activating the hammer function on the drill and using a 1/4 inch hex shank masonry drill include:

- Quicker drill bit changes saving time

- Stops drill bit spinning in drill chuck

- Quieter drilling

- Less vibration damage on hands

- Can drill closer to an edge

- Less risk of loosening mortar

- Less risk of damaging substrate

The 1/4 inch hex shank also prevents the carbide masonry drill bit from spinning in the chuck and allows quicker changes.

Quieter drilling

Using the hammer function on the dill during drilling in tough materials such as brick generates high levels of noise, potentially risking hearing damage and causing disturbances to others. Choosing non-hammer concrete drilling methods ensures quieter operations, reducing the risk of hearing damage and minimising disruptions to others.

Less vibration damage to hands

Frequent use of vibrating tools can result in hand injuries, including conditions like vibration white finger syndrome. Drilling without the hammer function on the drill reduces the vibrations caused by the, therefore reducing the risk of developing injuries and medical conditions like vibration white finger syndrome.

Can drill closer to an edge

When drilling with a hammer drill close to an edge, the hammer drilling can increase the chance of substrate breakage, especially in tough materials like concrete and brick. Choosing non-hammer drilling in concrete improves safety when working near an edge, reducing the risk of material breakage.

Less risk of loosening mortar

Hammer drilling on materials like concrete or brick can increase the chance of dislodging the brick or loosening or even breaking the mortar. No hammer drilling decreases the probability of such occurrences, allowing for better and safer drilling.

Less risk of damaging substrate

When hammer drilling tough materials like brick walls, there’s a risk of substrate breakage due to the hammer action impact on the brick. Drilling without the hammer function reduces the risk of substrate breakage, ensuring a safer drilling process.

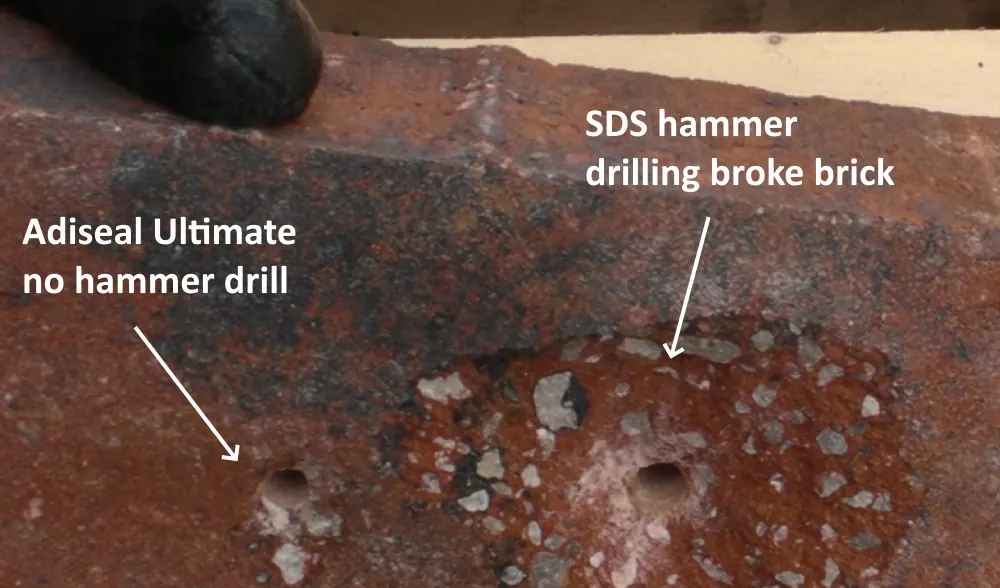

The image below shows a common problem when trying to drill through a brick wall with a SDS hammer drill bit. Due to the hammer impact on the brick wall, the SDS hammer drill bit usually breaks a big chunk out of the brick as it approaches the other side of the brick.

Adiseal Ultimate Hex Shank (No Hammer) vs SDS Hammer Drill Speed Test

In our test, employing the Adiseal Ultimate masonry drill bit & multi-material drill bit in a standard cordless drill without the hammer function achieved a drilling speed equivalent to a SDS hammer drill bit in a corded SDS hammer drill. Both drills took 5 seconds to bore into the brick. However, the SDS hammer drill resulted in the brick breaking, a common occurrence with hammer drills. Conversely, the Adiseal Ultimate masonry & multi-material drill bit, when used without the hammer function, did not cause any breakage to the brick.

How to use a hex shank drill bit

How to use a hex shank drill bit

- Insert the bit

Before inserting the hex shank drill bit, make sure the drill is switched off and the chuck is fully open. Hold the bit’s hexagonal shank and align it with the chuck’s jaws, then insert the bit until it’s properly seated in the chuck.

- Secure the bit

Depending on your chuck type, tighten it by hand or with the drill’s key or chuck collar. Rotate the chuck or use the provided tool to firmly secure the bit in place, ensuring it’s snug without any wobbling during use.

- Start Drilling

Turn on the drill and choose the right speed setting. Place the drill bit against the material you’re drilling into, applying steady pressure to start drilling at your preferred speed. Keep the drill perpendicular to the surface, maintaining control for precise and accurate drilling.

- Remove the bit

Once done, switch off the drill and loosen the chuck to release the bit. For a keyless chuck, rotate it in the opposite direction used for tightening. Gently pull the bit out from the chuck to remove it completely.

What materials can it drill into

Adiseal Ultimate hex shank masonry drill bit & multi-material drill bit can drill into many different materials including:

Sizes available

Adiseal Ultimate hex shank masonry drill bit (multi-material) is currently available in the following sizes:

- 4mm x 100mm

- 5mm x 100mm

- 5.5mm x 150mm

- 6mm x 150mm

- 6.5mm x 150mm

- 8mm x 150mm

- 10mm x 150mm

- 12mm x 150mm

- 12mm x 400mm (Extra long masonry drill bit)

Best metal drill bit

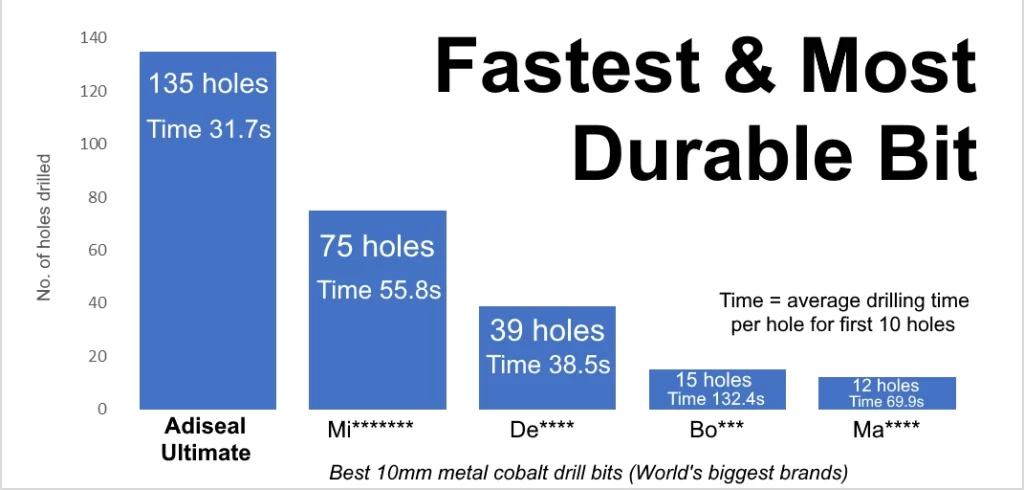

In their attempt to make available the best drill bits, also in the Adiseal Ultimate range is the fastest and most durable metal drill bit. In out test drilling into stainless steel with a drill press, it drilled faster and drilled more holes than any other metal drill bit. It was easily the best metal drill bit and it beat the best metal drill bits from the worlds biggest brands including Milwaukee, DeWalt, Bosch & Makita.

| 10mm metal cobalt drill bit | Total number of holes drilled (in 6mm stainless steel) | Time to drill each holes (average of 1st 10 hole) |

| Adiseal Ultimate cobalt | 135 holes | 31.7 seconds |

| Milwaukee cobalt red | 75 holes | 55.8 seconds |

| DeWalt Extreme cobalt | 39 holes | 38.5 seconds |

| Bosch cobalt | 15 holes | 132.4 seconds |

| Makita cobalt | 12 holes | 69.9 seconds |

Where to buy

To buy hex shank masonry drill bits in the UK, please contact us for details of you local stockist. For other countries that do not have a Adiseal distributor, please visit www.guglue.com

Frequently asked questions about hex shank masonry drill bit

The key difference between straight and hex shank drill bits lies in their shapes and how they fit into drills. Straight shank bits have a cylindrical shape and use a traditional chuck gripping method, often requiring a chuck key for securing. They are versatile and work with various drills. Hex shank bits, on the other hand, have a hexagonal shape that prevents slipping in the chuck. Specifically made for hexagonal chucks, they provide a secure grip without needing a chuck key. Hex shank bits are known for their quick-change feature, allowing rapid bit changes, notably in impact drivers and quick-change systems.

You can use hex shank drill bits if your drill’s chuck is compatible with them. Many drills can accommodate both round and hex shank bits. However, if your drill’s chuck is designed only for round shank bits and doesn’t securely grip hex shank bits, you might face slippage or instability while drilling. Always check your drill’s specifications or manual before using hex shank bits to ensure compatibility.

Hex shank bits offer numerous benefits: Their hex shape ensures a secure grip, reducing slippage during high-torque uses like impact drivers. They allow quick bit changes without extra tools, ideal for frequent swaps. Their design minimizes spinning, enhancing stability and accuracy. Versatile across drills, they offer efficiency, faster work, and less wear on bits and chucks, extending lifespan. Overall, their convenience, stability, and quick-change capability make them reliable for various tasks.

Not all drills support 1/4 inch hex shank bits. While many modern drills can use these bits, some drills may only accept specific bit types or sizes. Check your drill’s specifications or manual to confirm compatibility before using 1/4 inch hex shank bits. Some drills have chucks made for round shank bits and may not grip hex shank bits securely. Ensure compatibility to avoid slippage or instability while drilling.